Product Details

Product Description

OEM High Precision Custom Made 5 Axis CNC Machining Router DIY

Parts Oil Gas Machinery Parts Precision 5 Axis Machining Services

5 Axis Machining Services Description:

1. Hot sale metal precision machining parts,part cnc,precision

machining metal parts.

2. We have skills of cnc machine operation and can make machining

aerospace parts.

3. Small orders accep,we are cnc milling parts manufacturers.

5 Axis Machining Services Parameters:

| Material Capabilities | Aluminum, Brass, Bronze, Precious Metals, Hardened | Quality Assurance | ISO9001:2015 Certified | Material | Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc. | Brass Alloy:3600/ 3602 / 2604 / H59 / H62 / etc | Stainless Steel Alloy:303 / 304 / 316 / 412 / etc. | Steel Alloy:Carbon Steel / Die Steel / etc. | Other Special Materials:Lucite / Nylon / Bakelite / etc. | We handle many other type of materials. Please contact us if your

required material is not listed above. | Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel

plating,tinting | | Dimensions | Customer Required | Process | forging +CNC Machining | | Micro Machining or Not | Not Micro Machining | Application | Aviation, shipbuilding, power generation industry processing

propeller, engine, generator and turbine blade parts,Medical

equipment industry. | Standard | ASTM, ASME, DIN, JIS, ISO, BS, API, EN,GB | Company Advantage | 1. High Precision, New Technology, Competitive Price for Casting

and machining

2. Advanced casting machines available.

3. All kinds of facility, CNC machining, turning, milling, tapping,

drilling, polishing, punching, etc...

4. Competitive Prices, Excellent Service, and Good Lead Time. |

|

5 Axis Machining Services Advantage:

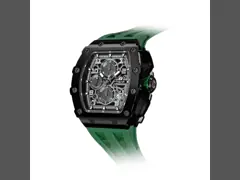

All the product pictures on our website just showing our machining

capability and ranges We offer

machining service according to customer's drawings or samples

1. Experience: more than ten years manufacturing history;

2. Price : Reasonable and competitive according to your drawings;

3. Quality assurance:To ensure correct standard and choose equivalent stansard for

materail and technique

requirements,before running ,we would like to provide formal

material certificate showing chemical compositions

and property,also if you need ,we can provide control plan,showing

processing and inspection tooling;

4. Quanlity control:In house,coming inspection,first off,spotcheck in processing ,final

inspection, 100% inspection

for critical dimension;

Company Profile

Fekon Precision CNC Parts Ltd was established in 2007 as a leading

manufacturer which is specializing in various CNC machining

parts.,including milling parts, turning parts,auto parts,carbon

fiber,watch parts,3D printing parts,cutting parts,with ISO 9001

Cerfifited.

There is 140 sets of equipments, 22 units CNC milling machines ,53

units computer wire cutting machines, 35 units milling machines ,

2 unites CNC lathes ,3 unit Three-dimensional measuring instrument

and 4 units 3D coordinate measuring machines.Equipped with

advanced 3-axis, 4-axis and 5-axis machining centers, we can

process parts with complex geometries at high precision. Our

engineers

use advanced programming CAM software combined with high quality

cuttingtools to produce parts efficiently and repeatedly.we have

own reserch and develop team,sales team,production team and QC

team,Our product quality and service are hightly recognized by

customers all over the world,it is honored to have customers around

the worldfrom America,England,Germany,Switzerland,Australia,

Singapore and etc.