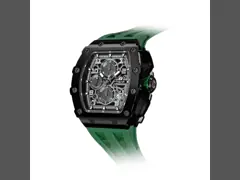

Aluminum alloy CNC lathe metal keyboard shell Non-standard hardware parts mechanical keyboard shell 3-axis cnc machining

Brand Name:custom cnc parts

Certification:ISO9001 and ISO14001

Model Number:FK-0038

Minimum Order Quantity:1pcs

Delivery Time:5~8days

Payment Terms:L/C, D/A, D/P, T/T

Contact Now

Add to Cart

Verified Supplier

Location:

Shenzhen China

Address:

Room 1502F, Building3A ,TianAn, Longgang District, Shenzhen City,China

Supplier`s last login times:

within 46 hours

Product Details

Company Profile

Product Details

Product Description

3-axis cnc machining parts Description:

1. On-site CNC milling, Mill stand machining,cnc rapid prototyping

2. CNC milling turning precision machining parts/ CNC parts/ CNC

lathe machining. Custom Precision

Machined Parts, China Machining Parts Solutions,cnc prototype

service

3. Small orders accept,we can custom best affordable cnc mill

parts.

| Surface Treatment | Powder coating, Eletro plating, Oxide,Anodization |

Brand Name | OEM/ODM |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Milling, Turning, Wire EDM, Rapid Prototyping |

MOQ | 1 piece |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys |

| Certification | Meet TS16949,ISO9001-2008 |

| Packing | PE Bag+Carton |

Looking for a competitive advantage, rapid turnaround supplier for

your CNC machining project?

we are an expert in CNC machining service in China for both CNC

prototypes and machined parts

of end-use. We provide CNC milling and CNC turning of various

materials, as well as drilling, tapping, EDM

(Electrical Discharge Machining), and wire EDM. Our ISO 9001

certified production process, combined with

professional machining experience and advanced CNC machines ensures

your parts are made right the first time,

every time.

Aluminum alloy CNC lathe metal keyboard shell Non-standard hardware parts mechanical keyboard shell 3-axis cnc machining

Inquiry Cart

0