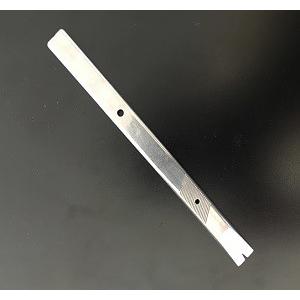

Scalpel Knives Injection Mold Components , Custom Metal Components Surgical Purposes

Add to Cart

MIM – What Is It?

1. Manufacturing technique for producing small, complex , metal parts

2. A combination of powder metallurgy and plastic injection molding technologies.

3. It is a cost effective alternative to machining or investment casting.

MIM – Why use it?

1. Economical production of complex parts with weight from 0.02 to 200g from high- performance engineering materials.

2. Parts with high dimensional precision (±0.1%~±0.5%) and good surface quality (surface roughness 1~5μm).

3. Parts with high relative density (95%~100%), homogeneous microstructure and superior performance.

4. Adaptable to powders of various materials and wide application of the parts.

| Item | MIM | PM | Precision | Machining Operation | Stamping |

| Denslty | 96% | 86% | 98% | 100% | 100% |

| Tenslle Strength | High | Low | High | High | High |

| Surface Finish | High | Medium | Medium | High | High |

| Small Size | High | Medium | Low | Medium | High |

| Thickness | High | Medium | Medium | Low | High |

| Complexity Level | High | Low | Medium | High | Low |

| Design Tolerance | High | Medium | Medium | Medium | Low |

| Capacity | High | High | Medium | Medium-High | High |

| Range of Applying Material | High | High | Medium-High | Medium | Medium |

| Supply Ability | High | High | Medium | Low | High |

Tolerances of MIM Products

Tolerances

5mm±0.025mm

10mm±0.05mm

20mm±0.10mm

40mm±0.15mm

Flatness 0.3%

Material System

Stainless steel(303,304,316L,420,440C,17-4PH)

High density alloys(W-Ni-Fe W-Ni-Cu W-Cu)

Carbon steel (Fe-2Ni,F-8Ni)