Add to Cart

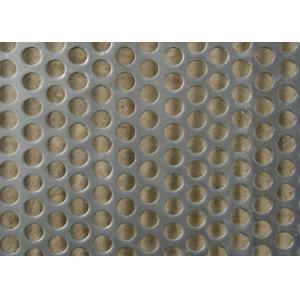

Ventilation Perforated Mesh Panel - Uniform Airflow with Reinforced Edges for Durability

Product Overview:

Our Ventilation Perforated Mesh Panel combines precise airflow control with industrial-strength construction. Featuring laser-cut perforations and reinforced border frames, these panels deliver 30% better airflow distribution than standard mesh while maintaining structural integrity under heavy loads. Ideal for HVAC systems, machinery guards, and architectural cladding.

Technical Data Sheet:

| Parameter | Specification |

| Material | Stainless Steel 304/316 |

| Thickness | 1.0mm - 5.0mm (Customizable) |

| Hole Pattern | Round/Square/Hexagonal (CAD File Accepted) |

| Hole Size | 2mm - 25mm Diameter (±0.05mm Tolerance) |

| Open Area Ratio | 25% - 60% (Precision Engineered) |

| Panel Dimensions | Max. 1500mm x 3000mm (Larger on Request) |

| Frame Reinforcement | 20mm Wide Border with 2.5mm Gusset Corners |

| Load Capacity | Up to 500kg/m² (Depends on Thickness) |

Key Advantages:

1.Superior Airflow Design

2.Industrial-Grade Durability

3.Corrosion Resistance

4.Aesthetic Flexibility

Applications:

1.HVAC & Industrial Ventilation

2.Machinery Protection

3.Architectural Solutions

4.Transportation

Manufacturing Process:

1.Laser Precision Cutting

2.Edge Reinforcement

3.Surface Treatment

4.Quality Control

FAQ:

Q1: What is the typical lead time for custom perforated panels?

A: Standard designs (pre-configured hole patterns/sizes) ship in

7-10 business days. Fully custom designs take 10-15 business days.

Q2: Can these panels be used outdoors in coastal areas?

A: Yes! Our 316 stainless steel panels with electrolytic polishing

withstand saltwater corrosion. For aluminum, specify marine-grade

anodizing.

Q3: What’s the weight difference between stainless steel and

aluminum panels?

A: Aluminum is ~50% lighter (e.g., a 1.5m x 1m x 2mm panel weighs

8.1kg vs. 16.2kg for stainless steel).

Q4: What’s the MOQ for custom designs?

A: 5 panels for testing/prototyping. Production MOQ is 50PCS for

standard materials.

Q5: How are panels packaged for shipping?

A: Each panel is foam-wrapped + crated with edge protectors. Frames

are palletized to prevent transit damage.

Request a Quote Today – Secure Your Perimeter with Unbeatable Quality!