Add to Cart

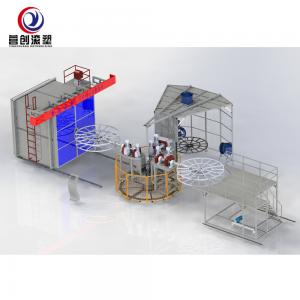

Rotational Molding Equipment is an advanced rock and roll rotomoulding machine designed for producing high-quality PE plastic products. It features electric heating, allowing users to enjoy efficient and timely production. The rotary moulding machine is multifunctional, offering a wide range of applications in the industry. Its durable and reliable construction ensures a long-lasting performance. Besides, it is backed by a 1-year warranty for extra peace of mind.

This revolutionary rotomoulding machine utilizes state-of-the-art electric heating technology, making it an ideal choice for mass production. It is designed to be highly efficient and cost-effective. It has a robust and reliable construction, making it a long-lasting and reliable product. Thanks to its multifunctional design, it can be used for a variety of applications. Besides, it is backed by a 1-year warranty for extra peace of mind.

Rotational Molding Equipment is a perfect choice for those looking for an advanced rock and roll rotomoulding machine. It is powered by electric heating and manufactured using high-quality PE plastic. It is designed to be highly efficient and cost-effective, offering a wide range of applications in the industry. Its durable and reliable construction ensures a long-lasting performance, while its multifunctional design makes it a great choice for mass production. Plus, it is backed by a 1-year warranty for extra peace of mind.

It only takes three minutes for the oven to reach temperatures from 250 to 280 degrees, starting from room temperature.

The arm is made of special alloy that is highly durable and supports a full-gear transmission, for an efficient full-automatic operation. Furthermore, the oven is heavy-duty and particularly energy-efficient.

Loading and unloading the mould is easy, thanks to the special deep cavity heating technology. It has been designed to handle even the most complicated products.

The machine also comes with internet remote control. Hence, in case of any problem at your factory, we are able to give assistance through the internet.

PLC and motors are from Siemens, Germany; burners from RIELLO, Italy; bearings from NSK, Japan; electrical components from Schneider.

You can take advantage of the big computer screen, bob-weight system, special-made motor, thermostability sealing arm head, among others. Additionally, the use of circular oven ensures more uniform heat distribution on the mould, which is great for product-making and helps save energy.

| Technical Parameters | Details |

|---|---|

| Service Life | Long |

| Capacity | High |

| Control System | PLC |

| Voltage | 220V, 400V |

| Applicable Industries | Manufacturing Plant |

| Type | Rotational Molding Equipment |

| Molding Method | Rotational Molding |

| Warranty | 1 Year |

| Power | Electric |

| Heating Mode | Electric Heating |

Rotational Molding Equipment, produced by Yingchuang, is a highly efficient and reliable machine with CE certification. It is designed for the manufacturing of water tanks or large parts with superior performance. It is equipped with electric heating, rotational molding and 220V/400V voltage. The minimum order quantity is one with wooden box and packaging cotton for safe delivery. The delivery time is within 40-60 working days. The capacity is high and size is customizable. The Supply Ability is 2-3 machines per month.

Rotational Molding Equipment is an ideal choice for shuttle rotomolding machine. It is cost-effective and has excellent thermal performance, enabling the production of high-quality tanks. It is widely used in water tank manufacturing and other large-scale production. The entire process is automatic and requires minimal manual operation.

Rotational Molding Equipment from Yingchuang is an ideal choice for large-scale production. The superior performance and reliability of the machine makes it an excellent choice for various industries and applications. It is cost-effective and easy to operate, making it a perfect choice for various production requirements.

We offer custom Rotational Molding Equipment with the brand name of Yingchuang. This equipment is made in Jiangsu, China, and is CE certified. The minimum order quantity is 1, and it is packed in a wooden box with packaging cotton. Our production capacity is 2-3 machines per month, and delivery time is less than 40-60 work days. The control system is PLC, and it is applicable to manufacturing plants. The warranty is for 1 year and size is customized. This machine is suitable for water tank making and rotary moulding.

Rotational Molding Equipment Packaging and Shipping:

The equipment will be packaged in a suitable wooden crate that

meets export requirements. The equipment will be securely fastened

within the crate and all loose components will be securely fastened

with either foam or bubble wrap. The crate will be clearly labeled

with the appropriate customs information and the consignee’s

address. The crate will be sealed and shrink-wrapped for additional

security. The equipment will be shipped via ocean or air freight

depending on the location of the customer.