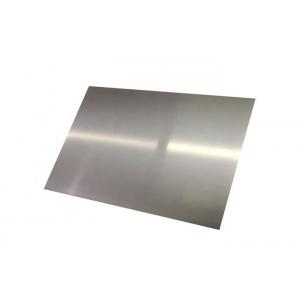

Mill Edge Super Duplex Plate , Polished Steel Plate Intercrystalline Corrosion Resistant

Add to Cart

1.4460, X3CrNiMoN27-5-2, AISI 329 steel - description and specification

Stainless duplex low-carbon steel resistant to intercrystalline corrosion, fatigue corrosion, crevice corrosion, pitting and stress corrosion. It exhibits excellent resistance to chlorides and, in addition, is susceptible to mechanical processing. It is characterized by high strength, hardness and good plasticity. Commonly used as steel for bearings in chlorine-containing environments.

However, in high temperatures of 300 - 900 ℃, the steel exhibits brittleness. With respect to duplex 1.4462 steel, the described grade has slightly worse corrosion resistance. Duplex 1.4460 steel products are used in the chemical, cryogenic, paper and aviation industries.

X3CrNiMoN27-5-2 steel is designed, among others, for pumps, screws, heat exchangers for power engineering, radiators, tanks, chlorine-bearing housings, valves, air constructions, pipelines, special anchors, pump shafts, stirrers and sleeves. In addition, the steel retains the resistance to intercrystalline corrosion after welding and in the delivery condition.

Mechanical and physical properties

- Tensile strength: Rm = 620 - 880 MPa

- Yield point: Re = > 460 MPa

- Hardness < 260 HB

- Elongation: A = > 20%

- Modulus of elasticity, E = 200 GPa

- Heat conductivity λ = 15 W ⋅ m-1 ⋅ K-1

- Heat capacity cp20℃ = 500 J ⋅ kg-1 ⋅ K-1

- Density: ρ = 7,80 kg/dm³

Steel Grades | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Chemical Composition % | |||||||||

C: | Mn: | Si: | P: | S: | Cr: | Mo: | Ni: | N: | |

| EN / DIN | X3CrNiMoN27-5-2 - 1.4460 - 4460 | ||||||||

| <0.05 | <2.0 | <1.00 | <0.035 | <0.030 | 25.0 - 28.0 | 1.30 - 2.00 | 4.5 - 6.5 | 0.05 - 0.20 | |

| AFNOR | Z 5 CND 27-05 Az - Z5CND27-05 Az | ||||||||

| <0.05 | <2.0 | <0.75 | <0.035 | <0.025 | 26.0 - 27.0 | 1.30 - 2.00 | 4.5 - 5.0 | 0.05 - 0.20 | |

| UNS ASTM | AISI 329 - S32900 - S 32900 - 7-Mo | ||||||||

| <0.08 | <1.0 | <0.75 | <0.040 | <0.030 | 23.0 - 28.0 | 1.00 - 2.00 | 2.5 - 5.0 | - | |

| UNS ASTM | S31200 - S 31200 - 44 LN - F 50 | ||||||||

| <0.03 | <2.0 | <1.00 | <0.045 | <0.030 | 24.0 - 26.0 | 1.20 - 2.00 | 5.5 - 6.5 | 0.14 - 0.20 | |

| UNS ASTM | J93371 - 25Cr-5Ni-Mo-N - CD6MN - A 781 Grade 3A | ||||||||

| <0.06 | <1.0 | <1.00 | <0.040 | <0.040 | 24.0 - 27.0 | 1.75 - 2.50 | 4.0 - 6.0 | 0.15 - 0.25 | |

| UNE | X8CrNiMo26-6 - X 8 CrNiMo 26-6 - F-3552 | ||||||||

| <0.10 | <2.0 | <1.00 | <0.045 | <0.030 | 24.0 - 27.0 | 1.30 - 1.80 | 4.5 - 7.0 | <0.10 | |

| UNE | X8CrNiMo27-05 - X 8 CrNiMo 27-05 - F-3309 | ||||||||

| <0.10 | <2.0 | <1.00 | <0.045 | <0.030 | 26.0 - 28.0 | 1.30 - 2.00 | 4.0 - 5.0 | - | |

| SS | 2324 - SS2324 | ||||||||

| <0.10 | <2.0 | <1.00 | <0.045 | <0.030 | 24.0 - 27.0 | 1.30 - 1.80 | 4.5 - 7.0 | - | |

Duplex Stainless Steel 329 was one of the earliest duplex steel which is reflected in its higher permitted carbon content. Its resistance to pitting (PREN about 32) and to crevice corrosion is below that of super duplex steels, therefore use in seawater is limited. Exposure to moderate and high temperature and less rapid cooling may cause embrittlement. Accordingly, design stress values in ASME II do not extend above 260°C for S32900. Impact values are high at room temperature. However, the proportion and orientation of ferrite in welds and base material may significantly affect toughness at subzero temperatures. One of the earliest duplex steel which is reflected in its higher permitted carbon content. Its resistance to pitting (PREN about 32) and to crevice corrosion is below that of super duplex steels, therefore use in seawater is limited. Exposure to moderate and high temperature and less rapid cooling may cause embrittlement. Accordingly, design stress values in ASME II do not extend above 260°C for S32900. Impact values are high at room temperature. However, the proportion and orientation of ferrite in welds and base material may significantly affect toughness at subzero temperatures. Availability : Alloy 329 is available as round / flat / sheet / hexagonal / plate/ square / coil / pipe & fittings. UNS S32900 Chemical Composition C(Carbon) 0.08%Max Fe(Iron) Balance Mn(Manganese) 1.0%Max Si(Silicon) 0.75%Max S(Sulphur) 0.03%Max P(Phosphorus) 0.04%Max Cr(Chromium) 23-28% Ni(Nickel) 2.5-5.0% Mo(Molybdenum) 1.0-2.0% UNS S32900 Physical Properties Density 7800kg/m3 Melting Range 1450-1510°C UNS S32900 Mechanical Properties Hardness Brinnel 230 Tensile Strength@Break 725Mpa/10500psi Min Tensile Strength@Yiel 550Mpa/79800psi Min0.2%offset Elongation@Break 25%Min in 2" Duplex Stainless Steel 329 also conforms, or is similar to EN/DIN 1.4460 and 00Cr25Ni5Mo2 / SUS 329J1 / AISI 329 / UNS S32900 / Brands SS44 / SS 2324 / Din X8CrNiMo27-5 / ASME SA268 / ASTM A268 / ASTM A511 / SS 14 2324 / SIS 14 2324 / 453S Duplex Stainless steel 329 can be used for heat exchangers, chemical tanks, refineries, shafts (marine, etc) pressure vessel parts, flanges, fittings & pipes for the oil and gas industries and offshore technology, paper industry, compressor parts and seawater desalination plants amongst many other applications. Machining performance Download UNS S32900 the mechanical properties of the report, the report provides detailed performance analysis and application. Principal Design Features One of the most widely used precipitation hardening grades in the business. While soft and ductile in the solution annealed condition, it is capable of high properties with a single precipitation or aging treatment. Characterized by good corrosion resistance, high harness, toughness and strength. Machinability Long, gummy chips characterize this alloys machinability. It can be machined in the annealed condition, however condition H1150M will yield best results. Post machining solution treatment of parts will be required prior to final hardening if machining in this condition. Heat Treatment CONDITION A--Soak at 1900 F (1038 C) for 30 minutes and cool below 60 F (16 C) for complete martensite transformation. CONDITION H 950- Treat Condition A material at 900 F(482 C) for 1 hour, air cool.. CONDITION H925, H1025, H1075, H1100, H1150- Soak solution treated material for 4 hours at specified temperature, air cool, CONDITION H1150M- Soak solution treated material at 1400 F (760 C) for 2 hours, air cool, then re-heat to 1150 F (620 C) for 4 hours and air cool. Welding Successfully welded by common fusion and resistance methods, this alloy should not be joined by oxyacetylene welding. AWS E/ER630 filler metal is recommended if required. Forging Soak for 1 hour at 2150 F (1177 C) prior to forging. Do not work below 1850 F (1010 C). Post-work solution treatment is required prior to final hardening.