Product Details

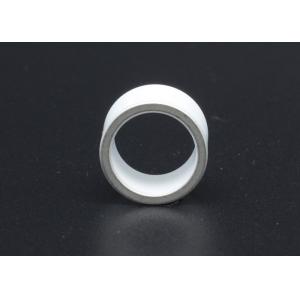

Magnetron Ceramic Rings With Metallized Layer

1. Description:

The magnetron series ceramics spare parts are produced by high

purity alumina and metallization ways. It is suitable for brazing

of different materials such as copper, aluminum, kovar and so on.

2. Key Words:

Magnetron, Microwave oven, Microwave generator, Radar microwave

generator,uniform texture and good batch stability,dense, continuous, flat

and weldable nickel layer,high flexural strength, high tensile

strength and good air tightness,high frequency, high power and good

safety components,Stable performance at high temperature circumstance,ceramic rings,microwave oven, microwave generator,high purity alumina.

3. Parameters:

| Product Parameters |

| Physical Property | Material | 95% Alumina |

| Production Process | Dry Pressing |

| Product Dimension | Per customers' drawing |

| Density (g/cm3) | 3.70-3.75g/cm3 |

| Water Absorption | 0% |

| Mechanical Performance | Flexural Strength (Mpa) | 310Mpa |

| Modulus of Elasticity (Gpa) | 310Gpa |

| Hardness (Gpa) | 12.9Gpa |

| Poisson Ratio | 0.23 |

| Thermal Character | Linear Thermal Expansion Coefficient | 7.2 |

| Heat Conductivity (W/mk) | 23 |

| Electrical Property | Dielectric Constant | 9.2 |

| Dielectric Loss Tangent (x10-4) | 8 |

| Insulation Strength (x106V/M) | 15 |

| Metalized Ceramic Performance | Air Tightness (Pa·m3/s) | ≤10-8 |

| Bulk Resistivity (Ω·cm) | ≥1010 (20°C), ≥106 (300°C) |

| Bonding Strength (Mpa) | ≥120Mpa |

| Metallization Thickness (μm) | ≥20μm |

Company Profile

Hunan Meicheng Ceramics Technology Co., Ltd. was established in

August 2010 with a registered capital of 36.8 million yuan. It is a

modern large-scale special ceramics enterprise integrating R&D,

production and sales. It passed the national high-tech enterprise

certification in 2014. The company is located in the Special

Ceramics Industrial Park of the Economic Development Zone of Xinhua

County with a beautiful environment, covering an area of 40000

Sq.m. It is the first enterprise to settle in the Special Ceramics

Industrial Park.

Meicheng consists of ceramics division, new energy division, sensor

division, brazing division, mainly engaged in the research and

application of zirconia ceramics, alumina ceramics, talc ceramics

and other non-oxide ceramics. The production mainly adopts dry

pressing process, supplemented by injection molding and tape

casting process, and expands 3D ceramic printing: It has advanced

ceramic nano metallization technology, ceramic brazing and ceramic

finishing capabilities.

Meicheng has a professional R&D and testing platform, a mold

making center and a raw material distribution base. And

successively established long-term industry-university-research

cooperation relations with Tsinghua University, Central South

University, Hunan University, Changsha University of Science and

Technology and other universities. Products are widely used in

electronic appliances, communication interconnection, electric

vehicles, urban light rail, aerospace, robotics and other fields.