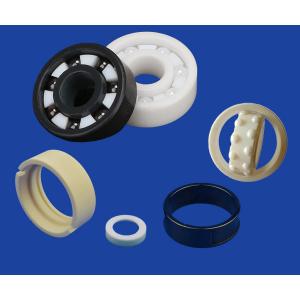

Alumina Oxide Hybrid Ceramic Bearings For Ceramic Insulating Sleeve

Add to Cart

High Temperatures And Corrosive Alumina Zirconia Ceramic Bearings

Full Ceramic Bearings have races and balls that are made entirely of ceramic material and are superior to common steel bearings in many ways. Ceramic is the perfect material for any application seeking to achieve higher RPM’s, reduce overall weight or for extremely harsh environments where high temperatures and corrosive substances are present.

Full Ceramic Bearings are usually made of following materials:

· Silicon Nitride (SiN4)

· Alumina Oxide (Al2O3)

· Zirconia Oxide (ZrO2)

· Silicon Carbide (SiC)

Because ceramic is a glass like surface it has an extremely low coefficient of friction and is ideal for applications seeking to reduce friction.

1. Material peroformance

Full ceramic bearing ZrO2 material

Full ceramic bearing ZrO2 material has great property such like suitable for low and high temperatures, high load capacity, corrosion resistance, nonmagnetic insulated and self lubrication. Thus it suit for the specific applications which are not available for bearing steel and hybrid construction ceramic ball bearing materials.

Full ceramic bearing Si3N4 material

Full ceramic bearing Si3N4 material has similar property as ZrO2

material, In addition; it has lower weight , better wear resistance, high hardness, and it can bear higher temperature than ZrO2 material.

2. Structures

Rings(ZRO2/SI3N4)+ Retainer(PEEK/PTFE/NYLON)+Ball( ZRO2/SI3N4)

Rings(ZRO2/SI3N4) +Ball( ZRO2/SI3N4) full ball without retainer

Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

Density | g/cm3 | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

Water absorption | 0 | 0 | 0 | 0 | 0 |

Poission`s ratio | / | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

Flexural strength | MPa | 310 | 950 | 390 | 720 |

Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

Electrical resistivity | Ω*mm2/m | >1016 | >1015 | >103 | >1013 |

Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

Dielectric strength | KV/mm | 8.7 | 9 | / | / |

Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

Modulus of elasticity young`s mod | GPa | 280-340 | 210 | 440 | 300 |

Flexural strength(700℃) | MPa | 230 | 210 | 380 | 450 |

Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

Resistance to acid alkaline | / | high | high | high | high |

Thermal shock resistance | T(℃) | 180-220 | 280-350 | 230-260 | / |

Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

Tensile strength | MPa | 248 | 250 | / | / |