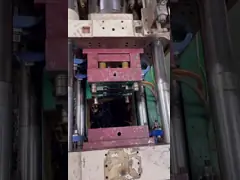

Polish Surface Precision Plastic Injection Moulding Lkm Dme Base Hrc 48

Add to Cart

PC / PP / POM Plastic Injection Mold , Plastic Electric Mosquito Killer Mould With LKM / DME / HASCO Base

Product Description

Looking for high-quality medical plastic injection molding services? Our SKD11/8407 medical plastic injection molding with multi-cavity ODM is the right choice for you.

Our SKD11/8407 material is known for its excellent wear resistanceand toughness, making it ideal for medical applications that require durability and reliability. With multi-cavity ODM, we can produce multiple parts in one cycle, reducing production time and costs while ensuring consistent quality.

Our team of experienced professionals uses advanced injection molding technology to produce precise and accurate parts that meet your specifications. We can also assist you with design optimization and tooling development to ensure optimal performance and cost-effectiveness.

1. Capacity: Your disign

2. good quality and competitive price

3. various color to choice

4. blow molding processing

5. Logo and label can be printed

6. OEM is available,we can also manufacture products according to your picture or samples.

| our commitment | All customer-centric,never betray long-term benifits for short-term benfits. |

| our scope of mould business | Mold,GARAGE KIT,injection molding,product assembly, surface printing,surface spraying integration |

| provide information as follow | 2D,3D,samples or pictures of multiple points of view with dimensions. |

| mould production cycles | 15--60days, on basis of the difficulty level |

| plastic products production cycles | 7--15days |

| mould precision | 0.1mm |

| service life | 500-1000 thousand times |

| cavity number of mold | Single cavity,Multiple cavity or one mold with different products |

| mould material | P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

| runner system | Hot runner , Cold runner |

| surface treatment | Words corrosion,Mirror polish,Frosted surface,Dermatoglyph |

| mould standard | HASCO,DME or according to custom's request |

| main process | Milling,grinding,CNC,EDM,wire-electrode cutting, carved, electrospark,lathe,surface treatment |

| design software | CAD, PRO-E, UG etc. |

| design time | Within 3 days(generally) |

| formed material | ABS,PP,PC ,PA6,PA66, TPU,POM ,PBT,PVC,HIPS,PMMA, TPE,PC/ABS,TPV,TPO,TPR,EVA,HDPE. |

| quality assurance | ISO9001 |

| factory profile | 6000 square meters,100 employees including 8 inspectors |

Application of Plastic Injection Molding

· Electric appliance: air condition, television, DVD

· Toys: car model, motorcycle model etc.

· Hardware: faucet, head shower, bath equipment, sanitary ware

· Digital product: computer, MP4, mobile phone, digital camera

· Transportation: automobile pat, instrument board etc.

· Medical treatment devices: massager, sphygmomanometer

· Telecommunication equipment: telephone, fax machine

Plastic injection mold advantages:

1. Professional design team

2. Professional mold design team

3. Professional mold making machines

4. Professional mould and product QC engineering team

5. Rich mold making experience with different clients from various

country