Product Details

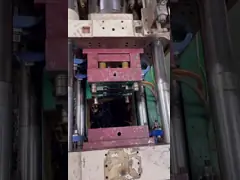

PA66 / PA OEM Trade Assurance Customized Injection Plastic mold

Specifications

plastic injection molding service

1.Single or mutil cavity

2.Hot or cold runner

3.PROE UG and CAD design

1 . Mould specifications

Material of steel

cavity and core use imported S136 stainless steel with fine

polishing, high hardness to get mold's high precision and good

quality.

About gate

pin-valve gate ,pneumatic drive the nozzle pin simultaneous high

speed open and close action. which can effectively control the

injection hole open and close actions on each cavity. reliable seal

function, smooth moving, low thermal expansion rate ,long using

life and also saves electric energy.

About hot runner

hot runner system is designed and made by ourselves, it can achieve

ideal and prompt heating effect for preform production ,cavity with

lower injection pressure to reduce wear and tear of mould parts.

Heat system

with double heating system,it has separate temperature control mode

,the heat bar are used to heat the mould mainfold plate,small

heaters supply the heating temperature for cavity nozzle

continuously.

Cooling system

each parts including core ,cavity and valve gate has independently

cooling system.

Company Profile

Company Information:Founded in 1993, WeiYU Precision Mould Factory

is a leading professional experienced manufacturer of plastic

injection mold in China.

Our professional staff are mastered of tool/mold making service

including plastic injection mould, die casting mould, blow mold and

metal stamping mold (die), At the same time our business category

is also involved in molded part producing such as plastic parts,

castings parts, plastic & metal over-mould parts, stamping parts,

rubber parts, and precision machined parts.

With self-built plant, the company enjoys a convenient

transportation, only ten minutes drive from the entries of

Dongguan-Shenzhen Expressway and Guangzhou-Shenzhen Expressway.

Our business philosophy is advancing with the times. The latest

software systems such as CAD, UG and PRO/E SOLID WORKS are applied

to the engineering design, which greatly help optimize the mould

designing. Additionally, high precise CNC, CNC EDM and other

advanced machines are well equiped in our plant. All of these

facility have tremendously promote our production capacity to a

higher level.

We provide adequate and systematic services from moulds to

injection molding production. With a group of senior technicians,

we are constantly devoted to improving quality and updating

technology.

We are determined to create the greatest values for customers with

unremitting efforts, first-class service and professional spirit.We

provide adequate and systematic services from moulds to injection

molding production.