Product Details

PC / PP / POM Precision Injection Molding , Plastic AUTO Mould With

LKM / DME / HASCO

plastic injection auto part mould advantages:

1.Professional design team

2.Professional mold design team

3.Professional mold making machines

4.Professional mould and product QC and tec. team

5.Rich mould making experience with different clients from various

country

Plastic injection auto part mould Special info.:

| Brand | Moldie |

| Model | MLD-13-MD101 |

| Process | Plastic injection mold |

| Mold Base | LKM, C50 standard mold base or other you want |

| Mold Material | H13, 1.2344, 1.2738 and so on to be chosen |

| Standard | HASCO, DME, MISUMI, PUNCH |

| Product Material | ABS, PC, PVC, PA66, POM or other you want |

| Certificated | ISO 9001:2008 Certificated, GSG Certificated |

Our professional engineers team design, make and check the mold in each step:

- Our engineers follow the molds' production every week to make sure all of them are in schedule;

- After trial production, we will check the samples to make sure all are right

- We will send the sample and dimension report to our clients for

approval

- After everything is ok, we will do final inspection on the molds and products before shipment.

Some other terms

| MOQ | 1 set mold |

| Sample lead time | About 4-7 weeks, according to the mold |

| Products lead time | About 4-6 weeks, According to your order |

| Payment term | T/T, L/C, Paypal |

| Mold payment term | 50%T/T deposit with PO , balance 50% T/T after sample approved |

| Products payment term | 30%T/T deposit with PO, balance 70% T/T before shipment |

| Port of loading | Shenzhen or HongKong port. |

| Package | Rust-proof protection, fresco bag, wooden case and pallet, suitable for shipment |

We are one of professional company to provide you good quality products with good price in time.

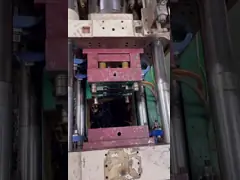

Below are some pictures about this mold and its product, hope you

could have a look:

Company Profile

Company Information:Founded in 1993, WeiYU Precision Mould Factory

is a leading professional experienced manufacturer of plastic

injection mold in China.

Our professional staff are mastered of tool/mold making service

including plastic injection mould, die casting mould, blow mold and

metal stamping mold (die), At the same time our business category

is also involved in molded part producing such as plastic parts,

castings parts, plastic & metal over-mould parts, stamping parts,

rubber parts, and precision machined parts.

With self-built plant, the company enjoys a convenient

transportation, only ten minutes drive from the entries of

Dongguan-Shenzhen Expressway and Guangzhou-Shenzhen Expressway.

Our business philosophy is advancing with the times. The latest

software systems such as CAD, UG and PRO/E SOLID WORKS are applied

to the engineering design, which greatly help optimize the mould

designing. Additionally, high precise CNC, CNC EDM and other

advanced machines are well equiped in our plant. All of these

facility have tremendously promote our production capacity to a

higher level.

We provide adequate and systematic services from moulds to

injection molding production. With a group of senior technicians,

we are constantly devoted to improving quality and updating

technology.

We are determined to create the greatest values for customers with

unremitting efforts, first-class service and professional spirit.We

provide adequate and systematic services from moulds to injection

molding production.