Product Details

Custom Rotational Molding Plastic Fuel Tank and Oil Tank with OEM

Rotomolded Service

Rotomolding Plastic Fuel Tank

The rotational molding process is quite clear and simplistic

relative to molding parameters. Heat is utilized to melt the

co-polymer resin in a closed mold cavity. When temperatures inside

the mold reach an estimated 257°F, melting occurs. The resin

material then flows to the molds inner surface and adheres to the

mold wall creating a substrate wall of plastic.

A three stage process is employed which includes mold loading and

discharge of finished product, heat and fusion in an oven

environment and finally the cooling cycle. Molds typically rotate

on a bi-axial motion which provides for a uniform substrate wall

throughout the entire finished product. Various materials are sold

and utilized in this process with the most widely used products

being polyethylene, polyurethane, PVC, polypropylene and nylon.

When compared to the many plastics arena’s that exist today, the

field of rotational molding cannot be surpassed. One of the largest

benefits in this area relates to tooling costs. When compared to

some of its counterparts a savings as sizable as 60% can sometimes

be achieved.

item | value |

Place of Origin | China |

| Jiangsu |

Brand Name | YOUGE custom |

Model Number | custom |

Plastic Modling Type | Rotational Molding |

Processing Service | Moulding, Cutting, OEM, manufacturing |

Product name | Plastic customization |

Color | Custom Color |

Material | LLDPE |

Shape | Customized Shapes |

MOQ | 100 Pcs |

Packing | export wooden box Plastic rotoplastic products : normally film and

carton board protected |

Logo | Customer Logo |

Mold Material | aluminium alloy |

OEM/ODM | OEM Service Provided |

Size | Custom Size Accepted |

rotational Mould : export wooden box

Plastic rotoplastic products : normally film and carton board

protected

1.Superior Quality The professional R&D dept of our company

having sufficient experiences in desingn and development. The

skillful team were capable of avoiding any mistakes during the

process of manufacture. 2.Competitive Price The cheap labor and

land could save large expenses,the cost of production is

accordingly low. We do our outmost to offer you the resonable price

in order to facilitate the cooperation between us. 3.Best Services

Our company is a leading export trade manufacture intigrating the

products development,manufacturer and sales together.We are

service-oriented and ensure that we can offer the best services to

you.

YOUGE is an ISO certified company. Quality is our standard.

our services

Company Profile

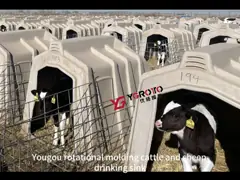

Jiangsu Youge Mould company focus on Rotational Moulds and

Rotomolding processing such as: fuel tanks, water tanks, cleaning

and environmental protection equipment, amusement equipment,

outdoor furniture, kayaks, pontoons, transportation facilities,

agricultural machinery parts , cold-chain insulation boxes and

other rotomold products .

Youge Factory covers an area of 8000 square meters ,the factory has

CNC machining centers, numerical control milling machines, electric

spark machines, wire cutting machines, fully automatic rotomolding

rotating molding machines, and other equipment to provide more

solid hardware support for production. We can process molds by

diameter of 3.5 meters, by length of 6 meters, by weight up to 1.5

ton. The annual production capacity is 1000 sets of molds and 1200

tons of products. 70% of the molds are exported to Europe,Oceania ,

North America , Asia and Africa ,30% molds for local rotomolders .

Youge factory offer One stop service for design and manufacturing

of Rotomold products , we aim at Quality first , Resonable price ,

Stable delivery time , Superior service to be your trustworthy

Rotomold supplier in China .