Product Details

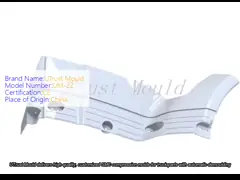

New Design Special Battery Box SMC mould/BMC mold for Car smc mold

factory

Utrust High Quality New Design Special Material Press Mold For Battery Box SMC mould/BMC mold for Car

profession design

precise manufacture

competitive price

Making the mold according to your drawing

Injection machine tonnage: 80-780 tons.

Mould Specification

Name: SMC mould

Mould material 45# ,50#,P20,H13,718,2738,NAK80,S316,SKD61 etc.

Mould base LKM,HASCO ect.

Cavity Single /multi

Runner Hot/cold

Design software UG ,PROE,CAD ,CAXA,ect.

Plastic material PP,ABS,PS,PE,PU,PVC,PMMA,ect.

Mould life 500,000-100,0000 shots

Delivery time 20-60days

Specification According to customer's requirements

Our Services:

1. Rich experience in the design and manufacturing of Plastik mould tooling 2. High quality , competitive price , on_time delivery and excellent service.

3. Customers's 2D, 3D drawing or samples are welcomed.

4. OEM & ODM orders are accepted

5. Our factory already passed the ISO 9001:2008 Certificated.

6. Three-eight-hour-shifts working system, ensure the efficient production.

Working Procedure:

1.R&D

We support customer R&D. Make the files or improve the design if you needed.

2.Negotiation

the quality, price, material, delivery time, payment item, ect.

3.Place an order

according your own design or you chooses our design.

4. Mould

According customers request to build the mould. Before make the mould, we send mould design to customer approval first, before move forward to production; we send samples to customer to confirm first.

5. Sample shoot

If the first sample come out is not satisfied customer, we modify the mould and until meet customers satisfactory.

6.Products in store

If your quantity is beyond our storage, we will provide lead time to you.

7. Delivery

Delivery goods by sea or by air, according customers requirement.

Company Information:

We can make all kinds of SMC mould for you. Please send the 2D/3D drawing or sample, mould life you require, cavity you need, then we will offer the detail quotation to you.

You are welcomed to visit our factory.

Company Profile

UTrust Mould Co., Ltd. is a leader in the design and manufacturing

of high-precision molds and comprehensive product solutions.

Located in Huangyan, Taizhou, Zhejiang, China , the company

specializes in composite material compression molding and plastic

injection molding.

With over 15 years of professional expertise , UTrust Mould serves a wide range of industries including

automotive, aerospace, military, and public infrastructure.

Our core business is built on a comprehensive product portfolio,

including molds for:

- Thermoset Materials: SMC/BMC/GMT/LFT-D/GMT compression molds.

- Advanced Composites: RTM/HP-RTM/PCM molds, as well as carbon fiber and autoclave molds.

- Thermoplastics: Molds for various thermoplastic composites.

At the heart of our operations lies a CAE-driven engineering and

R&D process. Our team performs structural stress analysis, mold

flow simulation, and topological optimization to ensure that every

mold is

optimized for performance and manufacturability before production

even begins. We view the mold not just as a tool, but as a

strategic asset that addresses our clients' indirect costs and

production pain points,

ultimately creating greater value for them.

Our manufacturing capabilities are grounded in precision and scale.

We operate with state-of-the-art equipment, including high-speed

CNC machining, large gantry CNC, and advanced EDM technologies.

This

allows us to maintain a general machining tolerance of ±0.01mm, and

a precision of 0.1mm for large components over 2000mm. Our facility

can handle molds up to 4M x 8M in size and weighing up to 80 tons.

We offer a transparent, end-to-end service model, from initial

project initiation and collaborative design reviews to real-time

manufacturing updates. Our process includes rigorous final

inspection, CMM

measurements, and comprehensive after-sales support, providing

everything from spare parts and process guidance to full production

tracking.

Our expertise is demonstrated through a variety of successful

projects, such as:

- PCM Battery Pack Top Cover Molds: A high-performance, large-scale production solution.

- RTM & HP-RTM Molds: For high-performance carbon fiber applications like propellers.

- SMC Compression Molds: Serving a range of industries from automotive bumpers and bathroom

fixtures to public facilities.

- Autoclave Forming Molds: For complex aerospace and automotive components.

- Kevlar Military & Protective Equipment Molds: Including solutions for bulletproof shields and helmets.