Add to Cart

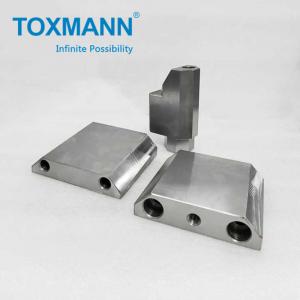

| Product Name | Plastic Mold Parts |

|---|---|

| Keywords | Plastic Injection Mold Parts, Custom Plastic Molding Accessories, Plastic Mold Parts, Plastic Die Mould, Quenching, Texturing, Polishing, Sample, FOB Shenzhen, Sprue Weight, High Polish With 2K, Dimension, Customized, Pro-E, Grinding Precision, Cold Runner |

| Shaping Mode | Plastic Die Mould |

| Surface Treatment | Quenching, Texturing, Polishing |

| Sample | Available |

| Term | FOB Shenzhen |

| Sprue Weight | 0.2g |

| Surface | High Polish With 2K |

| Dimension | Customized |

| Design Software | Pro-E |

| Grinding Precision | 0.001mm |

| Runner | Cold Runner |

Plastic Mold Parts, also known as Plastic Injection Mold Parts, are essential components in the production of plastic products. They are used to shape and form molten plastic material into specific shapes and sizes. These parts are widely used in various industries, including automotive, electronic, medical, and household appliances.

Plastic Mold Parts have a wide range of applications due to their high precision, durability, and cost-effectiveness. Let's take a look at some of the common scenarios where these parts are used.

In the automotive industry, where plastic components are extensively used, Plastic Mold Parts play a crucial role in creating various parts such as bumpers, dashboards, and interior trim. These parts are customized to fit the specific requirements of each car model, ensuring a perfect fit and finish. The high precision and durability of these parts make them ideal for use in the demanding and fast-paced automotive industry.

The electronic industry relies heavily on Plastic Mold Parts for the production of various electronic devices such as smartphones, laptops, and televisions. These parts are used to create the outer casing, buttons, and other components of these devices. The customized dimension and high precision of these parts ensure a perfect fit and functionality for each device, making them an essential component in the electronic industry.

In the medical industry, where precision and quality are of utmost importance, Plastic Mold Parts are widely used to create various medical equipment and devices. These parts are used in the production of items such as syringes, medical containers, and surgical instruments. The availability of samples and different drawing types allows for easy customization and production of complex medical parts, making them an essential tool in the medical industry.

Plastic Mold Parts are also widely used in the production of household appliances such as refrigerators, washing machines, and microwaves. These parts are used to create the outer casing, buttons, and other components of these appliances. The customized dimension and high precision of these parts ensure a perfect fit and functionality for each appliance, making them an essential part of our daily lives.

In conclusion, Plastic Mold Parts are a vital component in the production of plastic products. Their versatility, high precision, and durability make them suitable for use in various industries, including automotive, electronic, medical, and household appliances. With customized dimensions, availability of samples, and various drawing types, these parts offer a cost-effective solution for creating high-quality plastic products.

At Plastic Mold Parts, we understand the importance of timely delivery. That's why we offer a normal production time of 5-13 days for our customized services. We strive to meet our customers' deadlines and ensure that their projects stay on schedule.

Our cold runner system is designed to provide efficient and cost-effective solutions for plastic tooling hardware. With our cold runner, you can expect consistent and high-quality results for your plastic molding tooling accessories.

We specialize in plastic die moulds, offering a wide range of customization options to meet your specific needs. Our experienced team uses advanced techniques to create precise and durable molds for your projects.

With our high polish 2K surface treatment, we can provide a smooth and glossy finish for your plastic mold parts. This not only enhances the appearance of your products but also improves their overall quality and durability.

In addition to our 2K surface treatment, we also offer quenching, texturing, and polishing services to further customize your plastic mold parts. These treatments can provide additional strength, texture, and visual appeal to your products.

At Plastic Mold Parts, we specialize in providing customized services for plastic tooling hardware and molding accessories. Our team has the expertise and resources to cater to your unique needs and create custom plastic molding accessories according to your specifications. Contact us today to learn more about our customizable services.

Our Plastic Mold Parts are carefully packaged to ensure safe delivery to our customers. Each part is individually wrapped in protective material and placed in a sturdy box to prevent damage during transportation.

We offer various shipping options to accommodate different needs and budgets. Our standard shipping method is through reliable and trusted courier services, with tracking numbers provided for easy monitoring of the delivery status.

For urgent orders, we also offer expedited shipping options for faster delivery. Additional fees may apply for this service.

Our international customers can choose from a variety of international shipping options, including air freight and sea freight. Please note that additional fees and customs duties may apply for international shipments.

At Plastic Mold Parts, we strive to ensure that your order arrives in perfect condition and in a timely manner. Please contact us if you have any specific packaging or shipping requirements, and we will do our best to accommodate them.