Add to Cart

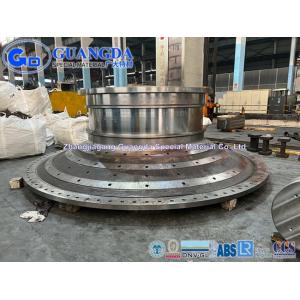

Customized Cast Steel Ball Mill End Cap Casting Foundry

Ball mill head cover is one of the key parts of ball mill, its structure is complex, production cycle is long, processing and assembly precision is high, so in the preparation of the process route, should give full consideration to its manufacturability.

The ball mill cap is mainly made of steel and alloy steel by casting, which can effectively make the shell cover achieve the best performance. The advantages of our shell cover are high hardness, good wear resistance, very popular with our customers. Large shell cover is widely used in cement, ball mill and other industries.

One-stop castings delivery capability

| Company type | Science and Technology innovation board listed company. Stock code :688186 |

| Annual capacity for the castings | 210,000.00 ton |

| Max length/Diameter | 15m |

| Max weight | 200T |

| Material | QT350-20 ,QT400-18, QT450-10,QT500-7, QT500-14,QT600-3, QT700-2, QT800-2 ,HT200, HT250, HT300,RUT300 etc. |

| Machining | Turning, milling, boring ,grinding, finished machining, gear shaping ,gear hobbing, gear grinding capability. |

| Heat treatment | Normalizing, QT, annealing, carburizing, nitriding with complete heat treatment capacity |

| Surface treatment | High-pressure cleaning, sand blasting and thermal spraying. Complete surface treatment capability. |

Large Iron Castins Main Casting Products

| Wind turbine casting parts | Rotor Hub, Nacelle head carrier , Main carrier, Main shaft ,Shaft sleeve, Torque arm ,Shell frame, Support base , Yaw base plate, Planet carrier ,Cover, Frame, Ring , Tower connection part, Nacelle connection part, All kinds of the structure parts for the widn turbines . |

| Equipment castings | Floor type boring machine castings ,Planner castings ,CNC machine castings, Milling equipment castings , Work bench ,Stand column, Equipment beam , Plastic mechanical castingsetc. |

| Large shell castings | Gear box shell ,Air cylinder castings, Front Box structure , Oil cylinder etc. |

| Structure support castings | Main bearing housing ,Planet carrier , |

| Disc and ring type castings | Flange ,grinding disc ,Grinding roller , solid of revolution etc. |

About Guangda Large Iron Castins

Guangda is a specialized in casting research and development, production, sales, service as one of the comprehensive company. Our business mainly focuses on large casting equipment, and our products mainly include large wind turbine castings, large equipment and equipment castings, large plastic machinery castings, and large shell castings. We have formed a whole industrial chain of smelting, casting, machining and surface treatment, and our technology and cost control are leading in the world.

Guangda Core Advantage Large Iron Castings

Smelting - casting - machining - surface treatment completed industry chain

High quality manufacturing proces

Continuous R&D and product innovation

Globle customer support

Through intelligent operation, one-stop, efficient to meet the product needs of customers

Continuously promote the optimization of industrial layout and the improvement of finishing efficiency

Provide more competitive casting comprehensive solutions for the downstream industry.

Smelting

Sand processiong line

Pouring casting

Casting machining line

Large Iron Castings products