Add to Cart

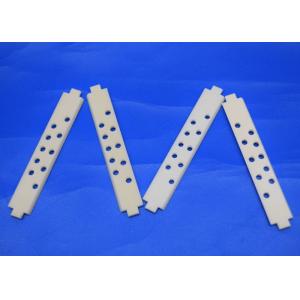

High Temperature Resistant 99.5% Al2O3 Alumina Ceramic Strips

Key words : Alumina Ceramic Strips

Mingrui 's Alumina Ceramic Strip provides the ability to withstand

higher temperatures (typically limited to 40 to 45 watts per square

inch, depending on the application). The heater consists of a

stainless steel sheath containing a high-temperature ceramic

insulating a nickel chrome wire coil. Magnesium oxide (MgO) is used

to fill any air pockets, thus providing the best heat transfer

possible.

The terminals are also constructed of stainless steel and are

securely anchored to prevent twisting out under normal conditions.

Several terminations are available, including water-resistance.

High-quality Alumina Ceramic Strips (aluminum oxide Al2O3 99.9%, 99.7% and 96% and zirconia ZrO2) are

present in low and high pressure injection valves. These components

are equally vital in any other switching valve systems where inert

materials resistant to the harshest solvents are required.

Mingrui manufactures high quality Alumina Ceramic Strips, made out of High Purity Alumina (97%, 99,7% or 99,9%) and TZP

Zirconia ceramics for high and low pressure injection and selection

valves. Rotors and Stators are subject to intensive mechanical

stress and chemical aggression while having to maintain a perfectly

leak free adjustment between the two components. No leak, limited

stiction and low wear are the most important parameters to

guarantee long life and reliability to your valve. These can be

achieved by an adequate surface finish, a perfect flatness of the

surfaces in contact and a proper selection of the material. Every

application is different and Ceramaret will help you define the

parameters required for your particular valve. Ceramic Rotors and

Stators are used in valves for many high-tech applications, such as

HPLC, micro-HPLC, Medical, Industrial, etc.

Typical Characteristics Rotor: Outside diameter: < 30,00 mm (

1.18") Thickness: < 7,00 mm ( . 28") Groove(s) dimensions: Width

> 0,051 mm ( .0002") Depth > 0,13 mm ( .0052") Length >

2,00 mm ( .0780") Stator: Outside diameter: < 30,00 mm ( 1.18")

Thickness: < 7,00 mm ( . 28") Hole diameter: > 0,22 mm x 0,25

mm (.008" x .010") Surface finish, Rotor or Stator Zirconia:

0,025 m (1 in) or N1 Alumina 99,9 %: 0,05 m (2 in) or N2

Alumina 96% or 99,7%: 0,1 to 0,2 m (4 to 8 in) or N3 to N4

Advantages of Alumina Ceramic Strips:

1. Isostatic pressed.

2. Fire resistance.

3. Superior mechnical strength.

4. High corrosion and wear resistance.

5. High Temperature Resistance.

6. Good Insulation Performance Precision.

7. Zirconia and alumina ceramic material.

They are high corrosion and wear resistance and strong impact

resistance and delivers 10 times longer working life than metal

plunger. They give a longer life to the sealed packing material.

Our Ceramic Strip heaters provide a dependable, versatile and

efficient heat source for a wide range of applications, such as:

They are available in many lengths. Whenever possible, please

provide a dimensional sketch of your requirements with your order.

Properties sheet of alumina ceramic :

| Properties | Units | 95 Alumina | 99 Alumina |

| Density | g / cm³ | 3.65 | 3.92 |

| Water absorption | % | 0 | 0 |

| Coefficient of thermal expansion | 10-6/K | 7.9 | 8.5 |

| Modulus of Elasticity Young's Mod | GPa | 280 | 340 |

| Poisson's ratio | / | 0.21 | 0.22 |

| HV Hardness HV | MPa | 1400 | 1650 |

| Flexural Strength @ room temperature | MPa | 280 | 310 |

| Flexural Strength @700°C | MPa | 220 | 230 |

| Compressive Strength @ room temperature | MPa | 2000 | 2200 |

| Fracture Toughness | MPa *m 1/2 | 3.8 | 4.2 |

| Heat conductivity @ room temperature | W/ m*k | 18-25 | 26-30 |

| Electrical Resistivity @ room temperature | Ω*mm2 /m | >1015 | >1016 |

| Max use temperature | °C | 1500 | 1750 |

| Resistance to acid alkaline | / | high | high |

| Dielectric Constant | / | 9.5 | 9.8 |

| Dielectric Strength | KV/mm | 16 | 22 |

| Thermol Shock Resistance | △ T ( °C ) | 220 | 180-200 |

| Tensile Strength @ 25 °C | MPa | 200 | 248 |

Product Photos Show

Packaging and Shipping

Packed in PP bag or sponge tray, then put in standard export carton

packing, or OEM packing.

Shipped by Air ( DHL, TNT, UPS, Fedex, EMS ), or Sea

transportation.

Company information

Who Are We?

Mingrui is a professional factory with years OEM experience in

manufacturing industrial ceramic parts.

What Do We Do?

We produce (OEM ) strengthened structure zirconia and alumina

ceramic rod,tube, shaft, plate, sleeve, valve, plunger, bearing,

nozzle and ceramic arm, they are applicable to instruments, medical

instruments, clocks and electronic products, mills, energy and

power, machine and metals, autocar and military, spaceflight and

some other high-end fields.

All of our products with certificates, such as , CE, TUV, and so

on.

Factory Show

Production Process Show

Certificates Show