Add to Cart

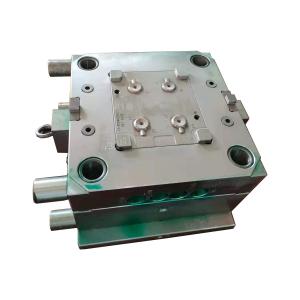

OEM ODM Custom Injection Mold And Molded Plastic Wall Switch Enclosure

Custom Injection Mold And Molded Plastic Wall Switch Enclosure

Custom 500000 Times Injection plastic parts for others like cosmetic case

Mold Information:

| Product Name | High Precision Mould |

| Mold Design software | PRO/E, Solidwork, UG, Autocad, etc |

| Mold Base | LKM,HASCO,DME,etc. |

| Mold Materials | S45C, P20, 718, 718H, 738, 738H, NAK80, SKD61, E420,ect. |

| Mold Cavity | Single, Multi, Family |

| Molding Material | ABS, PC, PP, PE, PA, PS,+GF, POM, PMMA,ect. |

| Molding color | Transparent, white, black, other solid colors according to customer's request |

| Surface finish | Texture, smooth, glossy or mirror polished ,VDI, EDM, SPI, YS, MT, etc. |

| Runner | Cold, hot runner such as YUDO. MASTER. SYNVENTIVE.etc. |

| Mold Life | 300,000~1,000,000cyces according to your requests |

| Lead time to T1 sample | 4~5 weeks |

| lead-time for production | 1~2 weeks |

| Tolerance | ±0.005mm |

| Services | OEM & ODM |

| Quality Management | ISO9001:2008 & TS16949 |

| Experiences | More than 20 years experience |

| Advantage | High quality, low prices, fast turnaround |

| Application | Quality mass production for your new product development, such as Household appliances, kitchenware, transportation tool, digital & telecommunication products, toys, auto parts, etc. |

Why choose us?

1.We are specialized in manufacturing plastic injection mould for over 11 years .

2.We own the CNC processing centers and various advanced mould tooling machine .

3.Our products possess the advantages of high precision, long life and short cycle with reasonable price,prompt delivery.

4.Mould design is subject to customers’ requirements.

5.Heat treatment of mold can be provided including quencher,nitridation,tempering,etc.

6.Our tenet is to manufacture customized and qualified mould as you required.

Work shop

Quality Control

FAQ About plastic injection moulding parts

Q1: How many injection plastic mouldings machines do you have?

A1: We have 40 sets of plastic Injection Mouldings machines.

Q2: what are the minimum & maximum unit weight and size your

machines can produce?

A2: Our machines produce unit parts from 1 gram to 6000 grams of

weight.

Our machines can produce the maximum size of unit plastic part:

1.5*1.5*1.5 meters.

Q3: What kind of plastic materials you usually use?

A3: We are specialized in producing plastic products with the

following materials:

PP, ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.

Q4: How do you pack the plastic molded parts?

A4: We pack the plastic molded parts by thick-wall cartons.

If the finished surface of plastic molded parts requires safe protection to avoid scratches, we will use a bubble plastic bag to pack the parts.

FAQ About Worldwide Delivery

Q5: Can you deliver the plastic moulds or plastic products to our

factory?

A5: Yes, We have cooperated with many international logistics

companies for years.

And we have full experience to manage the delivery directly to the

client's factory or appointed warehouse.

Q6: How does your factory do regarding quality control?

A6: Secure production under strict quality control system; Quality

is priority. 100% products tested. CE/ ROHS FCC/ Certification are

available if required.