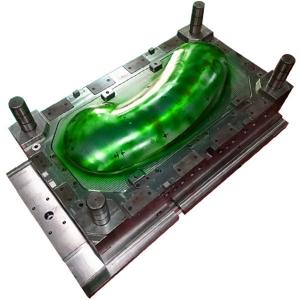

Pin - Point Gate Plastic Injection Tooling Cold Runner Auto Plastic Mould Part

Add to Cart

Pin-Point Gate Cold Runner Auto plastic mould part and tooling

| 2D drawing soft | Autocad |

| 2D drawing format | deg, dxf, pdf |

| 3D drawing soft | Pro-e, UG, Solidwork, MasterCAM, Catia |

| 3D drawing format | digs, iges, step, step, sldprt, etc |

| Mold base standard | LKM, HASCO, DME |

| Components standard | LKM, HASCO, DME, DADIO, Robordin |

| Mold steel | P20,718,738,H13,1.2312,1.2344,8407,SKD61,Nak80,S136, etc |

| Hot Runner Brand | YUDO, Mold Master, Mastip, DME, Thermplay, Gunter, Hot tip, |

| Mold Surface treatment | MT texture, YS texture, VDI texture, Polish, Mirror Polish, plating, etc, |

| Mold Size | 150*150mm<mold size<1500*1500mm (less than 15Ton) |

| Mold Life | 10,000 shots<mold cycle life<5,000,000 shots |

| Shipping method | Express, by air, by sea. |

| Services | 1.Product structure design |

| 2.Prototype making | |

| 3.Plastic mold design making and molding part | |

| 4.Die casting mold making and cast part | |

| 5.CNC machining | |

| 6.Cast part after-treatment process( polish, sandblast, anodize, plating) | |

| 7.Plastic part after-treatment process(paint, print, plating, water transfer printing) |

| Plastic Mold (Moulds) production process | Description |

| 1. 3d Design/Samples for quotation | According to 3D drawing or samples for quotation. |

| 2. Negotiations | Including the price of moulds, moulds sizes, material for cores & cavities, the weight of products, part cost, payment, moulds lifetime, delivery, etc. |

| 3. Purchasing Order | After the customer confirming the mould design and quotation. |

| 4. Making mold | Confirm drawing, start to do DFM, mold flows and mold detail agreed with the customer, start production. |

| 5. Production schedule | Every week we will feedback to the customer mold progress(picture). |

| 6. sample shoot | We provide the moulds test samples for confirmation(about 10-15 pieces), then, get your signature sample, mass production. |

| 7. Package | Wooden case for moulds, cartons for parts, or as your requirements |

| 8. Delivery | delivers goods by air or by sea. |

Howe, Engineering Design and Production Experts. Your One-Stop Global Plastic Solution.

We can customize various kinds of Plastic Injection Molds for each

customer according to their requirements. The quotation can be made

based on drawings or samples provided by customers. Our products

are both excellent in quality and reasonable in price. Your

satisfaction is our guarantee of survival!

Howe, a plastic injection molding company servicing the

- Medical

- Home Appliance

- Consumer Products

- Auto industry

With services ranging from Prototyping to serial production of high precision plastic parts and components, coupled with our vast experience and knowledge in Injection Molding technology. Those make Howe possible to provide a superior level of service to support your innovative concept to the real product.

Howe's value-added injection molding services include, but not limited to,

- Material selection and design advice

- Prototyping and production

- Plastic parts and component

Secondary processes - Ultrasonic welding

- Silk printing and Pad Printing

- Assemblies and Package

Howe provides innovative plastic solutions while delivering high-quality end products, and is fully versed in IQ,OP,PQ validation protocol and ISO 9001:2008 quality management.