Add to Cart

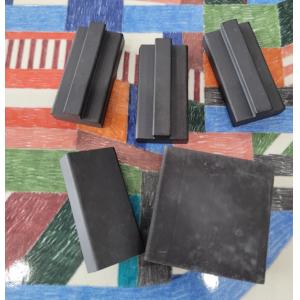

Precision-Machined Si3N4 Ceramic Element for Paper Sheet Formation

1 . Descriptions:

A precision-machined Si3N4 ceramic element for paper sheet formation is a component used in the papermaking process to improve the quality of the final product. The element is typically made of silicon nitride (Si3N4) ceramic, which is known for its high strength, wear resistance, and thermal stability.

The precision machining process allows for the creation of complex shapes and features that are critical in controlling the characteristics of the paper sheet being formed. These elements are often used in paper machine headboxes or forming sections, where the paper pulp slurry is distributed evenly onto a moving mesh screen or wire to form a wet web of paper.

The Si3N4 ceramic element is designed to provide consistent and uniform flow of the paper pulp slurry across the width of the machine, promoting proper sheet formation and reducing defects such as uneven thickness, porosity, and surface roughness. The high strength and wear resistance of the ceramic material also ensure long-lasting performance and minimize maintenance requirements.

Overall, the precision-machined Si3N4 ceramic element plays a critical role in ensuring high-quality paper products that meet the demanding specifications of various industries such as printing, packaging, and hygiene.

Product name | Paper Industry Dewatering Element Si3n4 Silicon Nitride Ceramic Part |

Material | Silicon nitride |

Size | Customized |

Color | Black |

Payment Item | T/T,Western Union,Online payment by credit card are available |

MOQ | 2 PCS |

2 . Advantages of silicon nitride ceramic parts

High hardness and wear resistance, both impingement and frictional

modes

Superior thermal shock resistance

Low thermal expansion

Electrical insulator

Good oxidation resistance

Good chemical corrosion resistance

Wear resistant

High stiffness

3 . Applications of silicon nitride ceramic

Welding pins, jigs, fixtures and nozzles

Turbine blades

Bearing balls and rollers

Cutting tools

Valves, turbocharger rotors for engines

Diesel engine glow plugs

Molten metal handling

Thermocouple sheaths

| Silicon nitride(Si3N4)Ceramic | |||

| Properties | Unit | Pressureless Sintered | Hot pressed |

| Bulk Density | Kg/m³ | 3.2×10³ | 3.25×10³ |

| Water Absorption | % | 0 | 0 |

| Mechanical | |||

| Porosity | %(%) | 0 | 0 |

| Color | - | Black | Black |

| Flexural Strength | MPa | 610 | 880 |

| Elastic Modulus | GPa | 290 | 300 |

| Vickerts Hardness | GPa | 13.9 | 14.0 |

| Maximun Use Temperature | ºC | 1000 | 1000 |

| Thermal | |||

| Thermal Conductivity | W/mk | 20 | 30 |

| Coefficient of Thermal Expansion | 10-6/ºC(4.-800ºC) | 3.2 | 3.0 |

| Thermal Shock Resistance(20ºC) | ΔT(C) | 550 | 750 |

| Electrical | |||

| Volume Resistivity | ohm*cm | >10^12 | --- |

| Dielectric Strength | V/m | 10×10^6 | --- |