Add to Cart

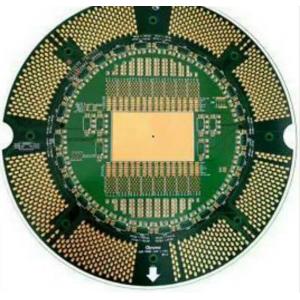

10 layersPCB,PCB Prototype Service,FR-4, TG150, inner and outer,PCB Prototype Service,pcb assembly prototype,pcb board

Product Description

In order to provide you with the most efficient and accurate quote on manufacturing the requested unit, we ask that you provide us with the following information

Surface treatment: full board OSP, full board immersion gold, whole board electric nickel gold, electric gold + immersion gold, electric gold + OSP, OSP + immersion gold, OSP + carbon bridge, gold finger, OSP + gold finger, immersion gold + gold finger, Shen tin, immersion silver, lead-free tin spray

PCB, FPC product application field

Various digital products, automotive new energy, automotive products, military, aerospace, medical, wireless terminals, wired terminals, communication equipment, communication stations, finance, industrial industrial control, consumer electronics, educational equipment, smart devices, smart products, security, LED, computer, mobile phone and other electronic products

PCB, FPC process production capability

| Technical ltem | MassProduct | Advanced Technology | |||||

| 2016 | 2017 | 2018 | |||||

| Max.Layer Count | 26L | 36L | 80L | ||||

| Through-hole plate | 2~45L | 2~60L | 2~80L | ||||

| Max.PCBSize(in) | 24*52" | 25*62" | 25*78.75" | ||||

| The layer number of FPC | 1~36L | 1~50L | 1~60L | ||||

| Max.PCBSize(in) | 9.8"*196" | 9.8"*196" | 10"*196"Reel to reel | ||||

| Layeredplatelayer | 2~12L | 2~18L | 2~26L | ||||

| Max.PCBSize(in) | 9"*48" | 9"*52" | 9"*62" | ||||

| Combination of hard and soft layers | 3~26L | 3~30L | 3~50L | ||||

| Interconnect HDI | 5+X+5Interconnect HDI | 7+X+7Interconnect HDI | 8+X+8,Interconnect HDI | ||||

| HDI PCB | 4~45L | 4~60L | 4~80L | ||||

| Interconnect HDI | 3+20+3 | 4+X+4Interconnect HDI | 4+X+4,Interconnect HDI | ||||

| Max.PCBSize(in) | 24"*43" | 24"*49" | 25"*52" | ||||

| Material | FR-4 Rogers | FR-4 Rogers | FR-4 Rogers | ||||

| Base material | Halogenfree,LowDK | Halogenfree,LowDK | Halogenfree,LowDK | ||||

| Build-up Material | FR-4 | FR-4 | FR-4 | ||||

| BOard,Thickness(mm) | Min.12L(mm) | 0.43 | 0.42~8.0mm | 0.38~10.0mm | |||

| Min.16L(mm) | 0.53 | 1.60~8.0mm | 0.45~10.0mm | ||||

| Min.18L(mm) | 0.63 | 2.0~8.0 | 0.51~10.0mm | ||||

| Min.52L(mm) | 0.8 | 2.50~8.0mm | 0.65~10.0mm | ||||

| MAX(mm) | 3.5 | 10.0mm | 10.0mm | ||||

| Min.CoreThickness um(mil) | 254"(10.0) | 254"(10.0) | 0.10~254(10.0mm) | ||||

| Min.Build up Dielectric | 38(1.5) | 32(1.3) | 25(1.0) | ||||

| BaseCopperWeight | Inner Layer | 4/1-8 OZ | 4/1-15 OZ | 4/1-0.30mm | |||

| Out Layer | 4/1-10 OZ | 4/1-15 OZ | 4/1-30 OZ | ||||

| Gold thick | 1~40u" | 1~60u" | 1~120u" | ||||

| Nithick | 76~127u" | 76~200u" | 1~250u" | ||||

| Min.HOle/Land um(mil) | 150/300(6/12) | 100/200(4/8) | 100/200(4/8) | ||||

| Min.Laser via/landum(mil) | 60/170(2.4/6.8) | 50/150(2/6) | 50/150(2/6) | ||||

| Min. IVH,Hole size/landum(mil) | 150/300(6/12) | 100/200(4/8) | 100/200(4/8) | ||||

| DieletricThickness | 38(1.5) | 32(1.3) | 32(1.3) | ||||

| 125(5) | 125(5) | 125(5) | |||||

| SKipvia | Yes | Yes | Yes | ||||

| viaoNhie(laserviaon BuriedPTH) | Yes | Yes | Yes | ||||

| Laser Hole Filling | Yes | Yes | Yes | ||||

| Technicalltem | Mass Product | Advanced Technolgy | |||||

| 2017year | 2018year | 2019year | |||||

| Drill hole depth ratio | ThroughHole | 2017year | .40:1 | .40:1 | |||

| Aspet Ratio | Micro Via | .35:1 | 1.2:1 | 1.2:1 | |||

| Copper Filling Dimple Size um(Mil) | 10(0.4) | 10(0.4) | 10(0.4) | ||||

| Min.LineWidth&space | lnner Layer um(mil) | 45/45(1.8/1.8) | 38/38(1.5/1.5) | 38/38(1.5/1.5) | |||

| Plated Layer um(mil) | 45/45(1.8/1.8) | 38/38(1.5/1.5) | 38/38(1.5/1.5) | ||||

| BGAPitch mm(Mil) | 0.3 | 0.3 | 0.3 | ||||

| Min.PTH Hole ring um(mil) | 75(3mil) | 62.5(2.5mil) | 62.5(2.5mil) | ||||

| Line Width Control | ∠2.5MIL | ±0.50 | ±0.50 | ±0.50 | |||

| 2.5Mil≤L/W∠4mil | ±0.50 | ±0.50 | ±0.50 | ||||

| ≦3mil | ±0.60 | ±0.60 | ±0.60 | ||||

| Laminated structure | Layer by layer | 3+N+3 | 4+N+4 | 5+N+5 | |||

| Sequential Build-up | 20L Any Layer | 36L Any Layer | 52L Any Layer | ||||

| Multi-layer overlay | N+N | N+N | N+N | ||||

| N+X+N | N+X+N | N+X+N | |||||

| sequential Lamination | 2+(N+X+N)+2 | 2+(N+X+N)+2 | 2+(N+X+N)+2 | ||||

| Soft and hard bonding | 2+(N+X+N)+2 | 2+(N+X+N)+2 | 2+(N+X+N)+2 | ||||

| PTH filling process | PTH resin plug hole + plating fill Electroplated hole/copper plug hole | PTH resin plug hole + plating fill Electroplated hole/copper plug hole | PTH resin plug hole + plating fill Electroplated hole/copper plug hole | ||||

PCB, FPC main material supplier

| NO | supplier | Supply material name | Material origin | |||||

| 1 | Japan | High frequency materials, PI, covering membrane,Copper berth | Mitsubishi Japan | |||||

| 2 | dupont | High frequency materials, PI, covering film, dry film,Copper berth | Japan | |||||

| 3 | panasonic | High frequency materials, PI, covering membrane,Copper berth | Japan | |||||

| 4 | SanTie | PI, covering membrane | Japan | |||||

| 5 | Born good | FR-4,PI,PP,Copper berth | shenzhen, China | |||||

| 6 | A rainbow | PI, covering membrane,Copper berth | Taiwan | |||||

| 7 | teflon | High frequency materials | The United States | |||||

| 8 | Rogers | High frequency materials | The United States | |||||

| 9 | Nippon Steel | PI, covering membrane,Copper berth | Taiwan | |||||

| 10 | sanyo | PI, covering membrane,Copper berth | Japan | |||||

| 11 | South Asia | FR-4,PI,PP,Copper berth | Taiwan | |||||

| 12 | doosan | FR-4,PP | South Korea | |||||

| 13 | Tai Yao plate | FR-4,PP,Copper berth | Taiwan | |||||

| 14 | Alight | FR-4,PP,Copper berth | Taiwan | |||||

| 15 | Yaoguang | FR-4,PP,Copper berth | Taiwan | |||||

| 16 | Yalong | FR-4,PP | The United States | |||||

| 17 | ISOAL | FR-4,PP | Japan | |||||

| 18 | OAK | Buried, buried resistance, PP | Japan | |||||

| 19 | United States 3M | FR-4,PP | The United States | |||||

| 20 | Bergs | Copper and aluminum matrix | Japan | |||||

| 21 | The sun | ink | Taiwan | |||||

| 22 | Murata | ink | Japan | |||||

| 23 | generous andbenevolent | PI, covering membrane,Copper berth | China's jiangxi | |||||

| 24 | Yasen | PPI, covering membrane | China jiangsu | |||||

| 25 | Yong Sheng Tai | ink | China guangdong panyu | |||||

| 26 | mita | ink | Japan | |||||

| 27 | Transcript | ceramic material | Taiwan | |||||

| 28 | HOME | ceramic material | Japan | |||||

| 29 | Fe-Ni-Mn | Alloy Invar, Section Steel | Taiwan | |||||

FAQ:

Q: What files do you use in PCB fabrication?

A: Gerber or Eagle, BOM listing, X, Y sitting report, PNP and Components Position

Q: Is it possible you could offer sample?

A: Yes, we can custom you sample to test before mass production

Q: When will I get the quotation after sent Gerber, BOM and test procedure?

A: Within 6-48hours for PCB quotation and around 24-48 hours for PCBA quotation.

Q: According to the difficulty of high-layer boards, How can I know the process of my PCB production?

A: 7-35days for PCB production and components purchasing, and 14-20days for PCB assembly and Testing

Q: How can I make sure the quality of my PCB?

A: We ensure that each piece of PCB, PCBA products work well before shipping. We'll test all of them according to your test procedure.