Add to Cart

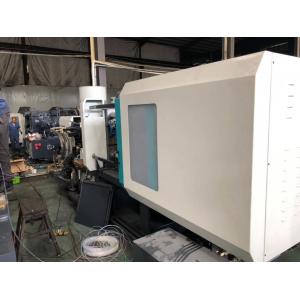

One Cavities feed trough injection Plastic Making Machine 290 Ton For trough

Production :

General purpose Injection Molding Machine is for small&middle

industrial parts, household appliances and other plastic products,

material PC, PP, PE, Nylon, A.B.S. PVC etc., suitable plastic

products weight 10g-630g, mold cavity can be: 1 Cavity, 2 Cavities, 3 Cavities, 4 Cavities, 6 Cavities, 8

Cavities, 10 Cavities, 12 Cavities, 16 Cavities, 24 Cavities

Main application

This is a new generation packaging machinery which is developed on the basis of introducing and absorbing the advanced technology from America, Japan and Germany. Adopts top quality components like Japanese Mitsubishi PLC, SMC pneumatic components, American Nordson hot melt adhesive, ensures the carton forming, packing, folding, glue spraying, sealing and the following packaging process continuously and automatically finished. With characteristics of reasonable structure, stable performance, reliable quality, high productivity, wide adaptability, and high degree automation. Widely used in instant noodles, cigarettes, liquor, beverage and other cartoon packaging products

Main technical parameters

| Product Name | 350 Injection molding machine price |

| Capacity | 10-15 cartoon/min |

| Table height | 800mm |

| Applicable size | (L)300-400×(W)300-450×(H)100-200 |

| Machine size | (L)5260×(W)1830×(H)2000 |

| Machine weight | 1600KG |

| Rated power | 4KW |

| Power supply | 380V 50HZ |

| Air supply | 150L/min 6Mpa |

| Hot melt adhesive | curing time 2-3 seconds,working temperature: 150-180°C |

Characteristics

(1) Energy saving

(2) High speed system response with short moulding cycles

(3) Significant working life of the hydraulic oil and hydraulic components, thereby reducing frequency of maintenance and maintenance costs

(4) The extra oil filtration requirements are met by special imported filter components

Shipping and Payment

| Product Name | 168 Injection blow molding machine price |

| Packing | Export standard package |

| MOQ | 1 set |

| FOB price | Please contact for new price |

| Delivery time | 60days |

| FOB port | Ningbo |

| Payment terms | T/T,L/C at sight |

1. Screw with optimum design enjoys features of good plasticity, high efficiency;

2. Big L/D ratio of plasticizing screw;

3. Adjustable back pressure control and melt decompression device;

4. Duel carriage cylinder to maintain consistent nozzle to platen alignment and

nozzle pressure, precision and consistency;

5. Linear potent ion meter for mould platen and screw position controls;

6. Injection screw directly driven by a low speed high torque hydraulic motor is

suitable for processing various plastics. The left diagram is to inject the sketch map.