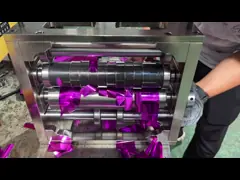

Product Details

High Performance Matt Finish Roller With Thermal Sprayed Coatings

MENGES HEAT TRANSFER & CHILL ROLLERS:

- Even temperature across rollface (+/- 1 degree), maintainable over

long production runs & linespeed variations

- Designed using Computational Fluid Dynamics (CFD) thermal models &

Finite Element Analysis (FEA) strength tests

- Variety of coatings & finishes available: chrome & mirror-finishes,

nickel, flame-sprayed and silicone-covered

FINISH & PLATING CHOICES:

For New Rollers or Refurbishing Projects

Chrome: Mirror, Optical Mirror & Super Finishes

Finishes May Be Polished to Any Ra Value

Nickel Plate

Thermal Sprayed Coatings

Acid Etched & Shot Blasted Matte Finishes

Black Chrome

Croydon Chrome (a satin finish)

Anodizing (for aluminum cores)

Knurled Textures

Cylindrical Grinding / Re-Grinding to Any Ra Value

Removal of Your Old Finish: For refurbishing projects, Menges has

in-house cylindrical grinding capabilities, to completely remove

your old finish & prepare it for new chrome, nickel, or whatever

you choose.

Use of Matt Finish Roller

The matt finish rollers are used for a multitude of applications

such as plastic film, paper, composite materials surface embossing,

and surface treatment. The rollers can also be used for different

appliances such as refrigerators, washers, dryers, and other small

appliances, automobiles, exposed as well as unexposed parts,

electric motors, bathtubs, etc. The intensity of the Matt Finish

Roll is specified as a surface roughness. The size and pattern are

customized.

Competitive advantage:

1) Top 5 in China for roller in China

2) High capacity in China, quick delivery time

Company Profile

The company is one of subsidiary companies for "ST.KEY

INTERNATIONAL GROUP S.A". Also the company has three factories in

China: embossing roller factory in Changzhou, LED light factory in

Kunshan, ceramic sanitaryware factory in Chaozhou.

The factory of embossing roller is located in Wujin Industry Area

in Changzhou China, and have high production capacity in China. Up

to now, we have become top 5 for embossing roller manufacturer in

China due to our large production scale and leading technologies.

With premium quality, we have gained a high reputation in both

domestic and overseas markets.

We control the procurement of raw materials strictly, relying on

abundant technology, importing and taking advantage of occident

advanced production techniques and equipment, improving our product

structure continuously, and controlling product quality strictly.

We also operate based on lean management and 5S management methods.

All our products are manufactured in accordance with Chinese, EU

and USA standards. Our R&D cente develops a lot of new products

according to our customer's requirements.

We have exported to many overseas markets such as Asian, North

American, South American, European, Middle East, African, etc.

The advantages for embossing roller factory are:

- More than 25 years experiences for producing rollers

- World class quality for roller

- Top 5 for embossing roller manufacturer in China

- High capacity in China, quick delivery time

- 5 “S” for lean management; continuous improvement encourage system