Product Details

Product Description:

ln casthouse applications, the control of grain size is absolutely

essential in maintaining product consistency and quality,reducing costs, and maintaining high levels of productivity. The

controlled addition of Aluminum’s titanium boron aluminium grain

refiners to molten aluminium releases nucleant particles that

promote equiaxed, fine grain structures throughout the cast

alloy,thus avoiding formation of columnar crystals. Casting speed

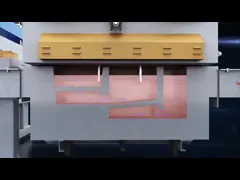

can also be increased. The wire feeder uses a variable frequency drive to control the

motor, achieving stepless speed regulation. The motor drives the

drum via a reducer, and under the action of the pressing wheel, the

wire is ejected. This main unit is equipped with a speed

setting device, a length setting device, and complete display

functions, ensuring accurate counting, stable operation, small

size,

and high power. It is an ideal wire feeding metallurgical equipment

for small to medium-sized smelting industries.

Basic Description of the Equipment

1. Equipment Name: Wire Feeder

2. Equipment Model: WF-10

* WF:Wire Feeder

* 10: Aluminum-Titanium Wire Diameter

3. Equipment Purpose: Mainly used to inject alloy cored wire into

molten aluminum at an appropriate speed and predetermined

quantity to achieve uniform dispersion, allowing for fine-tuning of

the composition.Technical Parameters:

| Motor power | Low Voltage Component From Zhengtai, VFD From SAJ |

| Rod Diameter | 8-13mm |

| Feeding speed | 1-2.5m/min, Variable Frequency Stepless Speed Regulation |

| Rod guide tube | 2 Pieces |

| Feeding rod number | 2 Rods |

| Feeding material | AlTiB Rod |

Company Profile

Founded in January 2003,Jinan HYDEB Thermal Tech Co., Ltd. is

located in Jinan High-tech Development Zone.

Hydeb mainly produces molten aluminum refining and degassing units,

molten aluminum transfer ladles and holding crucible furnaces,

which are sold to well-known corporations in the industry at home

and abroad, meeting their high requirements for product safety and

advancement.

Focusing on the aluminum casting industry, the Company takes

“Technology, Quality and Service” as its base of enterprise, aimed

at meeting all the needs of customers. Being “Safe, Practical,

Reliable, Efficient and nice-looking”, its products are well

unanimous recognized by the customers, with its brand “HYDEB”

gaining high popularity in the industry.

To meet the increasingly high requirements for aluminum casting

products, HYDEB gives full play to its technological superiority

and engages industry experts as technical directors, developing

products urgently needed in the market such as the counter (low)

pressure casting holding crucible furnaces and molten aluminum

refining and degassing units. It has also established long-term and

friendly partnerships with a number of large-scale Chinese

integrated equipment suppliers, sustaining its annual supply level

of more than 80 sets.

“Taking the lead and creating a brand name in the industry”. We

will continue to advance on the path of professional development

and continually improve our products and services to further meet

our customers’ development needs and support their creation of

greater values.