Product Details

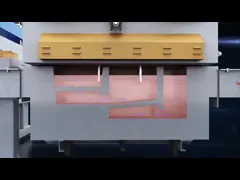

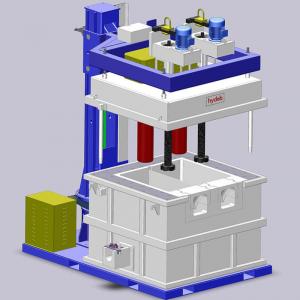

Aluminium Purification Box Type In-line Rotory Degassing Equipment

Equipment Features:

- Box Type Design: The equipment features a compact and sturdy box

type design, ensuring efficient and contained degassing operations.

It provides a controlled environment for the purification process,

minimizing the loss of heat and reducing exposure to impurities.

- In-line Rotary Degassing: With its in-line rotary degassing

mechanism, this equipment effectively removes hydrogen gas and

other impurities from the molten aluminum. The rotary degassing

action promotes thorough mixing and dispersion, resulting in

improved metal quality and mechanical properties.

- Precise Temperature Control: The equipment incorporates advanced

temperature control systems, allowing precise monitoring and

adjustment of the molten aluminum's temperature during the

degassing process. This feature ensures optimal degassing

efficiency and maintains the desired casting temperature.

- High Degassing Efficiency: Our equipment is designed to achieve

high degassing efficiency, effectively eliminating gas bubbles and

impurities. This leads to reduced porosity, enhanced casting

integrity, and improved surface finish of the final aluminum

products.

- Easy Operation and Maintenance: The equipment is user-friendly,

with intuitive controls and easy-to-follow procedures. It requires

minimal maintenance, ensuring smooth operation and reducing

downtime for maintenance activities.

Usage:

The Aluminium Purification Box Type In-line Rotary Degassing

Equipment is essential for aluminum foundries and casting

operations. It is used for the purification of molten aluminum,

particularly in processes where high-quality and defect-free

castings are crucial. The equipment is suitable for a wide range of

applications, including automotive parts, aerospace components, and

other precision-engineered aluminum products.

Investing in our Aluminium Purification Box Type In-line Rotary

Degassing Equipment guarantees improved casting quality, reduced

porosity, and enhanced mechanical properties of aluminum products.

Experience efficient degassing operations, precise temperature

control, and reliable performance with our advanced equipment.

Contact us today to discuss your specific requirements and unlock

the full potential of your aluminum casting processes.

Company Profile

Founded in January 2003,Jinan HYDEB Thermal Tech Co., Ltd. is

located in Jinan High-tech Development Zone.

Hydeb mainly produces molten aluminum refining and degassing units,

molten aluminum transfer ladles and holding crucible furnaces,

which are sold to well-known corporations in the industry at home

and abroad, meeting their high requirements for product safety and

advancement.

Focusing on the aluminum casting industry, the Company takes

“Technology, Quality and Service” as its base of enterprise, aimed

at meeting all the needs of customers. Being “Safe, Practical,

Reliable, Efficient and nice-looking”, its products are well

unanimous recognized by the customers, with its brand “HYDEB”

gaining high popularity in the industry.

To meet the increasingly high requirements for aluminum casting

products, HYDEB gives full play to its technological superiority

and engages industry experts as technical directors, developing

products urgently needed in the market such as the counter (low)

pressure casting holding crucible furnaces and molten aluminum

refining and degassing units. It has also established long-term and

friendly partnerships with a number of large-scale Chinese

integrated equipment suppliers, sustaining its annual supply level

of more than 80 sets.

“Taking the lead and creating a brand name in the industry”. We

will continue to advance on the path of professional development

and continually improve our products and services to further meet

our customers’ development needs and support their creation of

greater values.