Regenerative Gas Burner Used in YGL-1000Q Aluminum Melting Furnace

Add to Cart

Regenerative Gas Fired Melting & Holding Crucible Furnace YGL-1000Q Aluminum Melting Furnace Aluminum Scrap Melting

1. EQUIPMENT APPLICATION

• The equipment is used for the transportation and melting of aluminum scraps, and can be tilted hydraulically to pour the molten aluminum into the molten aluminum holding furnace.

• Type YGL-1000Q

2. EQUIPMENT COMPOSITION

| Name | Qty | Remark | |

| Mainly part | Furnace Body | 1 set | Without opeation platform |

| Hydraulic Tilting System | 1 set | ||

| Burning System | 1 set | ||

| Control System | Control System | 1 set | |

| Control Box | 1 pcs | ||

| Mixing Part | Mixing Device | 1 set | |

| Control Cabinet & System | |||

| Other Part | Crucible | 1 pcs | Option |

| Documents | 1 set | ||

3. EQUIPMENT FEATURES

3.1. Furnace Body

- Crucible furnace can be tilting by hydraulic system. And the furnace shell is made by welding the steel plate and steel, and other Q235 metal materials

- The chimney mouth of the tilting furnace faces the upper mouth of the crucible, and a "heat curtain" is formed on the mouth of the crucible to reduce heat loss in the crucible while heating from the upper mouth of the crucible.

- The bottom of the furnace body is provided with a liquid leakage port, and a liquid leakage probe is provided at the liquid leakage port. When the crucible leaks aluminum liquid, an alarm can be detected in time and the heating is cut off.

- The hearth at the bottom of the hearth is made of heavy refractory castable. The hearth lining material on the hearth side is made of heavy refractory bricks and fiber wool to form a composite lining. This combination of materials not only ensures that the lining has good thermal insulation properties, but also ensures that the lining can withstand the direct impact of the combustion flame.

- Temperature measurement thermocouple--A furnace temperature measurement thermocouple is used to measure and control the furnace temperature, and a aluminum liquid temperature measurement thermocouple is used to control the temperature of the aluminum liquid. There is a main and an auxiliary between the two, the main and auxiliary can be converted

3.2. Hydraulic Tilting System

- The crucible furnace is hydraulically tiltable. The tilting bracket is made of welded channel steel and steel plate to ensure sufficient strength and structural stability.

- The hydraulic system includes hydraulic station, electromagnetic directional valve, one-way throttle valve, hydraulic cylinder and other parts.

- One end of the hydraulic cylinder supports the fixed rotating bracket and can rotate along the support shaft, and the other end is fixed on the furnace body. When the piston rod of the hydraulic cylinder is pushed out, the furnace body is lifted up, and the furnace body is tilted along the rotation axis of the rotating bracket.

- The tilt control adopts manual operation of electromagnetic directional valve, which can stop or change direction at any time.

- Set travel switches at the two extreme positions of tilt to ensure tilt safety.

3.3. Burning System

- The burner is a Baltur automatic gas burner imported from Italy. The fuel is natural gas; the pressure of the gas is 5000Pa (the calorific value of natural gas is 8600 kcal/cubic).

- When the pressure of the combustion fuel drops to the lower limit (adjustable from 0-3000Pa), the pressure relay sends a signal to cut off the gas supply solenoid valve (comes with the burner). When the flame monitor can not detect the normal combustion of the flame, it will automatically cut off the gas supply solenoid valve and give an alarm indication.

- The burner is installed on a movable trolley, which is driven by the cylinder.

- Before the furnace body is tilted, the control system must ensure that the combustion tube of the burner exits from the combustion port of the furnace body in time.

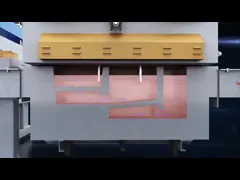

4. Equipment picture

5. MAIN PARAMETERS

| SN | Items | Data | Remarks | |

| 1 | Efficient furnace capacity kg (Al) | 750 | ||

| 2 | Melting Rate kg/h (Al) | 350 | Inside the crucible there is already have 1/3 molten aluminum. | |

| 3 | Burner | TGB60P | ||

| 4 | Energy Consumption m3/h | Around 40 | ||

| 5 | Maximum furnace temperature ℃ | 950 | ||

| 6 | Precision of molten aluminum temperature control ℃ | ≤± 5 | ||

| 7 | Temperature control mode | PID+Dual temperature control | ||

| 8 | Crucible type and size mm | ODΦ880, Height 1000 | TBN800 Morgen | |

| 9 | Furnace surface temperature rise ℃ | ≤50 | Except for the installation site of the heating tube, the discharge outlet and rising tube | |

| 10 | Gas Source | Gas type | Natural Gas | |

| Gas pressure | 5 Kpa | |||

| Max. Flow | 60 m3/h | |||

| 11 | Power Source | Voltage V | 380 | |

| Frequency HZ | 50 | |||

| Power Kw | ≤5 | |||

| 12 | Air Pressure MPa | 0.5-0.7 | ||