Add to Cart

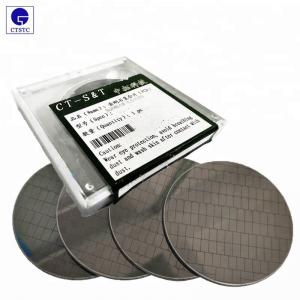

DIAMOND CUTTING TOOLS BLANK POLYCRYSTALLINE BLANK PCD BLANK FOR METAL CUTTING AND WOODEN CUTTING

CHN-TOP Blanks

Based on the good cooperation with foreign well-known enterprises and scientific research institutions, after years of digestion, introduction, absorption of foreign advanced technology and ideas, we have successfully developed a whole series of polycrystalline diamond blanks(PCD).

And after a long time of testing and practical application, the comprehensive performance of the product(Wear resistance, impact toughness, conductivity, stability, etc.)has approached the international level.

Name: Polycrystalline Diamond

Brand: CT-S&T

Type:

M series-Machining nonferrous metals and nonmetal

W series-Machining nonmetal, especially for woodworking

W series

| Model | Grit Size (Um) | Thickness (mm) | Diameter (mm) | Abrasive Resistance | Toughness | Conductivity | Performance | Application |

| ZT10W | 10 | 1.0/1.6/2.0/3.2 | 47.0/55.0 | Middle | Middle | High | Middle grit,good combination property, easy to WEDM | Woodworking, circuit board, plastic, composite,etc |

| ZT025W | 28 | 1.0/1.6/2.0/3.2 | 47.0/55.0 | High | Middle | Middle | Rough grit, long tools' life, could be WEDM | Laminate floor, graphite, sintered ceramic and carbide, composite, etc. |

| ZT302W | 30/2 | 1.0/1.6/2.0/3.2 | 47.0/55.0 | High | Middle | Middle | Good edge quality and strength maintaining, excllent abrasive resistance and thermal stability good EDM machining | Application areas include high silicon aluminum alloys, hard cast

irons and bi-metal |

M series

| Model | Grit Size (Um) | Thickness (mm) | Diameter (mm) | Abrasive Resistance | Toughness | Conductivity | Performance | Application |

| ZT005 | 5 | 1.0/1.6/2.0/3.2 | 47.0/55.0 | Low | High | High | Fine grit, precision finishing, easy to WEDM | Alumium alloy, copper alloy, noble metal, circuit board, etc. |

| ZT10M | 10 | 1.0/1.6/2.0/3.2 | 47.0/55.0 | Middle | Middle | Middle | Middle grit,wide range of machining | Low silicon alumium alloy, copper alloy, graphite, plastic, composite,etc. |

| ZT025M | 25 | 1.0/1.6/2.0/3.2 | 47.0/55.0 | High | Middle | Low | Rough grit, long tools' life | High silicon alumium alloy, graphite,plastic, composite,etc |

| ZT302M | 30/2 | 1.0/1.6/2.0/3.2 | 47.0/55.0 | High | Middle | Low | Excellent wear resistance,edge strength,edge quality and good thermal stablity | Application areas include high silicon aluminum alloys, hard cast irons and bi-metal |

Machining Service at CHN-TOP

| Carbide Inserts | Notching, Grinding |

| PCD/PCBN Blank | Laser cutting according to the size |

| Brazing service | PCD PCBN diamond brazing service |

| Grinding | Indexable inserts grinding service |

CHN-TOP is the company offer comprehensive solutions for diamond tools making

With more than 20 years of experience in diamond tools materials, we have a very good relationship with world famous PCD&PCBN blanks' manufacturers and distribute all brands of PCD&PCBN Blanks

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufactory for PCD,CBN diamond tools equipments and

service, we have our own R&D

team and production workshop. We can develop our customers' unique

products according to their needs.

Q: How long is your delivery time?

A: Generally it is 2-3 days for CNC diamonds tools machining, and

45-60 days for machines.

Q: How about your after-sales system?

A: We have a comprehensive after-sales system, which can provide

one-on-one online video service

according to the needs of customers, and one-on-one service to

solve customers' worries.

Q: How about your delivery date for PCD/PCBN blank?

A: 1), PCD/PCBN Blank, we have signed a Chinese agency agreement

with international big brands,

customers do not need to worry about genuine and delivery problems;

2), We can provide a wide range of products with PCD/ PCBN Blank,

customers can choose goods according

to different needs, we also have self-developed domestic PCD with

high quality, the price is very competitive.

Q: How about the cutting thickness and width of Laser cutting

machine?

A: 1), Cutting thickness, single-sided cutting maximum thickness of

4-5mm, double-sided cutting maximum

thickness of 8 10mm.

2), Slit width: 0.05-0.15mm, accuracy can reach 0.01mm.