Digital Automatic Coffee Cup Welding Machine Ultrasonic For PVC

Brand Name:Chuangyu

Certification:CE,CCC

Model Number:CY-CF600

Minimum Order Quantity:Automatic Coffee Cup Welding Machine 1 Set

Delivery Time:35- 45 working days

Payment Terms:T/T, Western Union, MoneyGram

Contact Now

Add to Cart

Active Member

Location:

Dongguan Guangdong China

Address:

No. 3th, Eastern Road, Xiangxi Industrial Area, Liaobu Town, Dongguan city, Guangdong Province, China

Supplier`s last login times:

within 24 hours

Product Details

Company Profile

Product Details

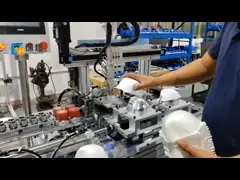

Automatic Coffee Cup Welding Machine

Description:

This machine is used for ultrasonic welding equipment between the

plastic filter cup and filter layer of disposable coffee powder and

tea powder. Conveyor type one-out three-structure design. Manual

whole drum feeding on the feeding conveyor line. The whole paper

roll is incoming. Automatic die cutting and unloading. The edge

material is automatically wound. The filter paper is automatically

assembled into the filter cup mold through the suction cup

manipulator. The filter paper is automatically indented and formed

by the mold. After forming, ultrasonic welding. Automatic feeding.

Note counting and feeding function. Simple and convenient

operation. Safe to use, safety gratings are installed in key safety

parts. The equipment is beautiful in appearance. memory function.

Features:

1. Use of original imported super-power transducer.

2. Integrated structures, adoption of a safety scale adjustment control.

3. Computer intelligent control, accuracy is up to thousandth of a second

4. Mold level adjustment, frame-mode simple and quick

5. Automatic body -motor up, down, the first in domestic.

6. Base level regulation , frame-mode fast.

2. Integrated structures, adoption of a safety scale adjustment control.

3. Computer intelligent control, accuracy is up to thousandth of a second

4. Mold level adjustment, frame-mode simple and quick

5. Automatic body -motor up, down, the first in domestic.

6. Base level regulation , frame-mode fast.

What is ultrasonic welding process? Ultrasonic welding is a solid-state welding process in which

joining of materials (metals and plastics) occur without melting.

In ultrasonic welding, high-frequency mechanical vibrations are

transferred to the parts to be joined, which cause sliding one part

over another.

Ultrasonic welding is an especially gentle joining technology for

thermoplastic materials and nonferrous metals. Manual work stations

are used in many ways in the plastics processing industry. The user

manually loads the plastic components to be joined and removes them

again from the ultrasonic welding machine after the weld process.

The components can be welded with one or more ultrasonic sonotrodes

depending on their size and geometry. Partially automated solutions

support the work process for the production of high-quality

thermoplastic products, but we also offer suitable platforms for

copper and aluminum, i.e. for LI battery and cable harness

applications. The development and production of all Chuangyu's

ultrasonic welding machines, whether they are series or customized

machines

Digital Automatic Coffee Cup Welding Machine Ultrasonic For PVC

Inquiry Cart

0