Add to Cart

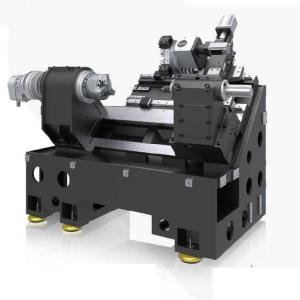

Product Description:

Product Features:

1,Increase spindle torque, increase bearing specification, provide more power and rigidity, A2-8 spindle

| Items | Unit | HTC40B/500 | HTC40B/1000 | |

| Maximum swing diameter over bed | mm | Φ600 | Φ560 | |

| Maximun cutting length | mm | 500 | 970 | |

| Maximum cutting diameter | mm | 400 | 400 | |

| Maximum swing diameter on the slide | mm | Φ320 | Φ350 | |

| Spindle nose | mm | A2-8 | A2-8 | |

| Spindle hole diameter | mm | Φ80 | Φ80 | |

| Diameter of maximum through bar | mm | Φ65 | Φ65 | |

| Spindle speed range | r/min | 50-3500 | 50-4000 | |

| Spindle maximum output torque | Nm | 245 | 177 | |

| Main motor | KW | 15/11 | 15/11 | |

| Chuck diameter | inch | 10'' 10'' | 8'' | |

| X-axis fast moving speed | m/min | 30 | 30 | |

| Z-axis fast moving speed | m/min | 30 | 30 | |

| X-axis travel | mm | 200 | 200 | |

| Z-axis travel | mm | 550 | 1050 | |

| ailstock stroke | mm | 100 | 100 | |

| Tailstock spindle taper taper | Mohs | 5# | 4# | |

| Standard tool holder form | mm | Horizontal 8 station | Horizontal 8 station | |

| External knife | mm | 25×25 | 25×25 | |

| Boring bar diameter | mm | Φ40/Φ32/Φ25/Φ20 | Φ40/Φ32/Φ25/Φ20 | |

| Weight capacity(Disk type) | kg | 200 | 200 | |

| Weight capacity(Shaft parts) | kg | 500 | 500 | |

| Machine weight | kg | 4200 | 4650 | |

| Machine tool appearance | Length × width × height | 2700×1900×2100 | 3570×1860×1850 | |

Industry application:

OUR Service:

1. Assemble and debug before delivery

FAQ:

Q1. Are you a trade company or manufacturing company?