Add to Cart

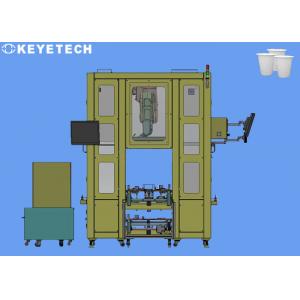

Cups And Bowls AI Visual Inspection System With OEM Design Plan

Inspection standard

| Model | Number Of Camera | Inspection Scope | Inspec | Precision | Accuracy | Speed |

| Kvis-Sc11 | 1 Set | Front Area | Black Spot, Stains | ≥0.5mm | 99% | 200pcs/Mins |

Chromatic Aberration | - | 99% | ||||

| Folds | - | 99% | ||||

| Broken | Width≥0.5mm Length≥1.0mm | 99% | ||||

| 4 Sets | Outside Area | Black Spot, Stains | ≥0.5mm | 99% | ||

Chromatic Aberration | - | 99% | ||||

| Folds | - | 99% | ||||

Notches, Burrs | Width≥0.5mm Length≥1.0mm | Notches, Burrs | ||||

| Broken | Width≥0.5mm Length≥1.0mm | Broken | ||||

| 1 Set | Concave Area | Black Spot, Stains | ≥0.5mm | Black Spot, Stains | ||

Chromatic Aberration | - | Chromatic Aberration | ||||

| Folds | - | Folds | ||||

| Deformation | - | Deformation | ||||

| Broken | Width≥0.5mm Length≥1.0mm | Broken | ||||

| 1 Set | Front Area | Thinning | Width≥0.5mm Length≥1.0mm | Thinning | ||

| Perforation | Width≥0.5mm Length≥1.0mm | Perforation | ||||

| 4 Sets | Outside Area | Thinning | Width≥0.5mm Length≥1.0mm | Thinning | ||

| Perforation | Width≥0.5mm Length≥1.0mm | Perforation | ||||

| - |

Inspection principle

According to the actual detection requirements of the paper cup production line, based on machine vision technology and image processing technology as the method, aiming at the product defect characteristics on the production line, an automatic detection system for disposable paper cup defects is designed, which effectively improves the efficiency of product defect detection.

The system is mainly composed of industrial camera, lens, LED ring light source, display, PLC, industrial control PC, photoelectric sensor, alarm device and image processing software.

Inspection details

When the system is running, the photoelectric sensor detects the movement of the production line, transmits the signal to the PLC, the PLC receives the input signal, triggers the industrial camera to work, and collects the image of the product to be detected through the cooperation of the lens, and transmits it to the industrial control PC. Through the analysis and processing software, the industrial control PC can judge whether the product has defects according to the image. If there is a defective product, the PLC will receive the rejection signal, sound the alarm device, and remind the worker to confirm.

Image preprocessing: binarize the collected image, fit the contour of the bottom circle of the cup by dividing the region of interest (ROI) and use the least squares method, determine the center of the circle, and position the paper cup. Then, various defects are detected on the paper cup. If the characteristic value of the detected defect is within the allowable range, it is qualified; otherwise, it is rejected.

Establish ROI area: Due to the structural characteristics of the paper cup itself, the paper cup can be divided into three areas: the bottom area of the cup, the side wall area, and the seam area. Due to the different gray levels in different areas, the set defect detection threshold will also change. The setting of the region of interest can reduce the detection range and greatly shorten the processing time of the system on the premise of ensuring that the characteristics of the detection region remain unchanged.

After-sale service