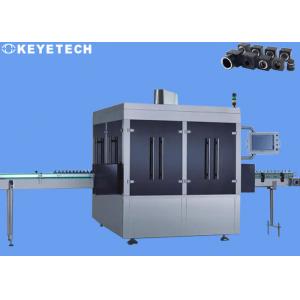

Product Details

AI Visual Inspection Solutions Built For Quality Control In The

Manufacturing Industry

Our advantages

| 1. AI algorithm: high stability, adapting to the environment and

background disturbance; different defect samples can be

automatically identified after training |

| 2. Dataization: Independent database, save multiple samples,

analyze non-good products, and retain history |

| 3. Multi-orientation: 360 ° comprehensive inside and outside the

samples |

| 4. High precision: detection accuracy can be high |

| 5. Modularization, can flexibly increase or decrease the detection

function according to customer actual needs |

| 6. Easy to operate: It is easy to operate and easy to maintain |

| 7. Safety: Medical grade material manufacturing, fully compliant

with medical supplies production environment |

Manufacturing and Artificial Intelligence

According to a Google Cloud survey, manufacturing companies are

making more use of AI and big data due to the COVID-19 pandemic,

with 66% of manufacturers using AI indicating that they are

increasingly relying on AI.

Deploying artificial intelligence in manufacturing to assist daily

operations

Research shows that companies using AI in their day-to-day

operations are primarily for business continuity assistance (38%),

using AI to improve employee efficiency (38%), and to help

employees overall (34%). And artificial intelligence, or machine

learning, can improve worker efficiency by providing prescriptive

analytics, flagging safety hazards or detecting potential defects

on the production floor.

AI is generally used for quality inspection, product/line

inspection, supply chain management, inventory management, etc.

Visual Inspection AI solution

The manufacturing process typically consists of one or more steps,

many of which require the product to be visually inspected for

defects. Often, visual inspection is a highly manual process that

is time-consuming and error-prone. Rule-based visual inspection

machines have also emerged over the years, but each approach has

drawbacks:

- Manual inspection depends on operator perception and experience

- Traditional inspection machinery requires programming, which is

inflexible and cannot adapt to product changes

- Existing machine vision-based inspections can only detect a few

defects at a time

- Manufacturing is no stranger to innovation, from mass production to

lean manufacturing to 6 Sigma and, more recently, enterprise

resource planning

Artificial intelligence (AI) promises to bring more innovations to

the forefront. In theory, there are multiple benefits to using AI:

- Reduce operator cognitive load and reduce errors

- No programming required, adapt to product changes

- Detect hundreds of areas of interest for products in seconds

Industry applications

Currently, the Visual Inspection AI (Visual Inspection AI) has been

used in the following industries and usage scenarios, such as

specific quality control issues:

- Automotive manufacturing: paint shop surface inspection, body shop

weld inspection, stamping shop inspection (scratches, dents,

cracks, staining), cast engine block inspection (cracks,

deformations, abnormalities)

- Semiconductor manufacturing: wafer-level anomaly and defect

location, chip crack detection, pre-positioning inspection, SoC

packaging inspection, circuit board assembly inspection

- Electronics Manufacturing: Defective or missing printed circuit

board (PCB) components (screws, springs, foam, connectors, shields,

etc.), PCB soldering and bonding (insufficient solder, icicles,

shifting, over-tin, etc.), product surfaces Check (glue spillage,

mesh deformation, scratches, air bubbles, etc.)

- General Manufacturing: Packaging and Label Inspection, Fabric

Inspection (Mesh, Tear, Yarn), Metal and Plastic Weld Inspection,

Surface Inspection

Company Profile

About Us

| Anhui Keye Intelligent Technology Co., Ltd has always been committed to the application of artificial

intelligence in the field of vision technology, replacing human

eyes and brain decision with machine vision and AI reasoning

calculations, and integrating the quality detection and sorting to

industrial products in traditional manufacturing to make the

production more digitization , Intelligence, visualization, and

persistence. Also greatly improves the efficiency and accuracy of

industrial detection, and enhances the intelligent level of the

manufacturing industry. |

Development History

The technology center is composed of algorithm department, software

department, optics department, hardware department and mechanical

department. The algorithm team currently has 7 PhDs, ensuring that

the AI algorithm has the ability to continuously update.

Organization Structure

Company Capability

Visual Inspection Solution

Vision Applications

Cooperation Partners

**Integrity, focus, innovation, excellence, Keyi technology is

committed to becoming A global visual inspection product provider,

to provide customers with leading technology, cost-effective

products and efficient services.

**We have a strong research and development team and mastered the

core technology, developed some cameras, lenses and light products,

laying a foundation for the future sustainable development. |