Add to Cart

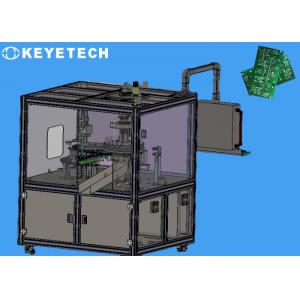

Automated PCB Optical Inspection System With AI Machine Vision Inspection

Inspection principle

The materials are arranged by vibrating plate, Linear vibration and non-destructive conveying, and the capacitance is stably and orderly transferred to the specific inspection station, and then the high-pixel sample image captured by the industrial camera is transferred to the image processing software. After the system analyzes and processes, it judges good and defective products, and controls the corresponding pneumatic components to eliminate the defective products, and finally collects qualified products.

Inspection details

sets of high-pixel industrial cameras and high-performance stroboscopic light sources to carry out omni-directional visual inspections for product appearance defects. The inspection speed is 300-400 pieces/min. The equipment can realize 7*24 hours of all-weather operation, and it can be online automatically. Eliminate substandard products.

The whole set of inspection equipment includes mechanical, visual electronic hardware and inspection system software. The entrance and exit of the equipment are reserved for docking positions to facilitate on-site operations.

| Equipment parameters | |||

| Name | Electrolytic capacitor appearance inspection machine | Model | KVIS-DR |

Weight | 300-500kg | Voltage | AC220/50HZ |

| Power | 3KW | Pressure | 0.2-0.8Mpa |

Conveying method | Vibrating plate feeding, non-destructive conveying | Inspection method | Online real-time inspetection |

| Camera type | High-speed industrial camera | Number of cameras | 14 sets of camera |

Algorithm | Deep learning | Compatible product size | Φ8-10,12,13 |

Speed | 300~400/min | Inspection scope | Poor appearance, poor size, mixed specifications, etc. |

Rejection method | High-speed automatic rejection | ||

Mechanical part

The mechanical part is the core component of the system, which carries all the transmission devices and electronic hardware (industrial cameras, light sources, industrial computers, touch screens, electrical boxes, etc.). The conveyor is controlled by a servo motor, and the image capture is accurate. The equipment is equipped with two defective product inlets to separate serious defective products (such as drum bottom, oblique leather tip, etc.) and general defective products.

Advantages&Machining Process

1.AI algorithm: high stability, adapting to the environment and background disturbance; different defect samples can be automatically identified after training.

2.Dataization: Independent database, save multiple samples, analyze non-good products, and retain history.

3.Multi-orientation: 360 ° comprehensive inside and outside of the PCB

4.High precision: detection accuracy can reach 99%.

5.Modularization, can flexibly increase or decrease the detection function according to customer actual needs.

6.Easy to operate: It is easy to operate and easy to maintain.

7.Safety: Medical grade material manufacturing, fully compliant with medical supplies production environment.