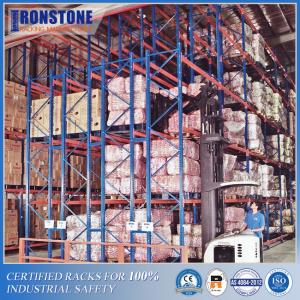

Double Deep Pallet Racking With Economical Storage Solutions

Add to Cart

Economic High-Density Double Deep Pallet Rack System for Industrial Storage

Double deep pallet racking is a pallet storage system used in facilities to increase the efficiency and density of pallet storage. A set of double deep pallet racks includes two sets of standard selective racks which are aligned back to back to form a double deep pallet storage system. Operators use double-reach or deep-reach forklifts to load and unload pallets from double-deep pallet racking systems.

These double-deep racks are often designed to be placed against a wall or attached to another double-deep racking section to maximize space utilization rate. Double deep racking is often found in warehouses with LIFO inventory cycles where productivity is high but space is limited. Double deep pallet racking system is able to maximize storage space by increasing space utilization rate by 60-65%.

| Name | Double Deep Pallet racking | Material | High Strength Steel-/American Standard Steel |

| Beam levels | 2~15 tiers per bay rack | Color | (RAL Code) Green, Orange, Blue, Yellow, Etc. |

| Upright Frame Height | 2500mm~15000mm | Weight Capacity | 500~3000kg per level |

| Beam Width | 1000mm~3900mm | Frame Depth | 700mm~1500mm |

| Finish | Epoxy Powder Coated for corrosion prevention | ||

| Usage | Cargos Storage | ||

| Package | Plastic stretch film, corrugated paper, Cartons, wooden bars, crates, and metal strips, etc. | ||

| Accessories | Bolts and nuts, Upright protectors, decks, etc. | ||

| Certification | RMI/AS4084-2012 /CE/ ISO9001 | ||

| Delivery time | 7~25 days as per order quantity | ||

| Assemble & installation | Detailed assembly instructions are available as well as dispatching installation engineer for project installation at the site. | ||

Each selection slot has a front and a back pallet. From the aisle, the forklift operator will access the front pallet at first and the back pallet is able to get access after the front pallet is removed, forming a LIFO (last in first out) stock rotation order. The last stored pallet will be the first one to pick up.

Double deep racking will increase your capacity with a tight budget. Similar to selective pallet racks, double deep pallet rack is available in a variety of heights, depths, bay lengths, and capacities and can be combined with rows of pallet racks allowing for a customizable solution.

Features and Advantages of Double Deep Pallet Racking System:

- Increase storage density by reducing space occupied by working aisles.

- In double deep pallet racking system, 50% of pallets can get immediate access and the other 50% of pallets are not available unless removing other pallets. Thus, it is suitable for warehouses that don’t need 100% immediate access to all pallets.

- Storage density is more important than stock rotation.

- Flexibility can be achieved by expanding your facility or re-configuring your storage systems.

- It is an economical solution among all high-density storage solutions.