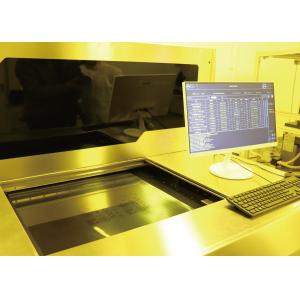

Laser Direct Imaging LDI Machine Flexible Board 260x810mm

Add to Cart

laser direct imaging (LDI) system solutions LDI Flexible Board

The interconnection complexity of HDI PCB is still growing today. Existing technologies are unable to offer acceptable solution for fine lines. But laser direct imaging technology is considered as an answer for this challenge.

In printed circuit board (PCB) manufacturing, the imaging process is what defines the copper circuit patterns. While the conventional imaging process adopts a photo-tool and UV light to transfer circuit images, LDI only uses a computer-controlled, highly focused, laser beam to directly define the circuit patterns on the PCB CCL copper layers with laser photoresist covered.

PCB laser direct imaging (LDI)

When fabricating a circuit board, the circuit traces are defined by

what is the imaging process. Laser direct imaging ( LDI ) exposes

the traces directly with a highly focused laser beam that in NC

controlled, instead of flooded light passing through a photo tool,

a laser beam will digitally create the image.

How does laser direct imaging ( LDI ) work?

Laser direct imaging needs a PCB with the photo-sensitive surface

that is positioned under a computer controlled laser. And then the

computer is creating the image on the board with the light of

laser. A computer scans the board surface into a raster image,

matching the raster image to a pre-loaded CAD or CAM design file

that includes the specifications for the necessary image intended

for the board, the laser is used for directly creating the image on

the board.

| Specification/model | RTR315 |

| Application | PCB,HDI,FPC (inner layer,outer layer,anti-welding) |

| Resolution (mass production) | 15um |

| Capacity | 12S@18"*24" |

| Exposure Size | 260*800mm |

| Panel thickness | 0.05mm-3.5mm |

| Alignment Mode | UV-Mark |

| Alignment capability | Outer layer±12um;Inner laye±24um |

| Line width tolerance | ±10% |

| Deviation increase and decrease mode | Fixed increase and contraction, automatic increase and contraction, interval increase and contraction, partition alignment |

| Laser type | LD Laser,405±5nm |

| File format | Gerber 274X;ODB++ |

| Power | 380V three-phase alternating current, 6.4kW,50HZ, voltage fluctuation range + 7% ~-10% |

| Condition | Yellow light room; Temperature 22°C ± 1°C; Humidity 50% ± 5%;

Cleanliness level 10000 and above; Vibration requirements to avoid violent vibration near the equipment |

About us

We are an innovative supplier of various PCB laser direct imaging

(LDI) system solutions. Our system product portfolio ranges from

LDI system configurations for high-mix and emerging PCB niche

applications to fully automated LDI system solutions for mass

production environments.