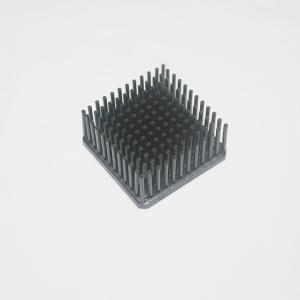

Square Cold Forged Heat Sink Anodizing Black Color For Video Camera

Add to Cart

Square Black Cold Forged Heat Sink For Video Camera Heat Sink With Anodizing Black Color

Quick Detail

| Raw Material | AL1070/1060 |

| Custom Service | Yes, OEM/ODM Service |

| Quality System | ISO9001:2015 |

| Processing Technology | Forged/cutting/laser/CNC/Anodizing |

| Surface treatment | Anodizing black |

| Packing Way | Blister packaging or special packing you would like |

| Application Scenario | Electronic equipment heat sink |

| MOQ Request | 100/500/1000 |

Description

This cold forged heat sink is based aluminum 1070 material to processing, first of all, we check the raw material dimension is fine or not, the second is that according to the drawing, use Hydraulic press machine to do the roughcast, the third is that accroding to the drawing, use the wood machine to cut the outline dimension, the forth is that use the CNC to do exact dimension, the fifth is do anodizing clear, the last step is riveting, and then inspection/packing. First inspection and patrol inspection are done in processing.

Note

Cold forged heat sink

An added benefit of this process is that a forged heatsink of the same design can be manufactured with different heights using only one set of forging die. When working with high aspect ratio, or dense fins a forged heatsink has no thermal interface between the fins/pins, and the base which will provide better performance compared with stamped-fin or bonded-fin heat sinks. Heat distribution can be further improved in aluminum heatsinks by embedding a copper inserts into the base during the forging. As this process is fairly expensive, for small volumes it may be worth exploring extrusion with a cross cut to produce square pins. For larger volumes die cast is a good alternative.

Fodor has gained experiences in the manufacturing techniques for high power cold forged heat sink. We have resolved the problems such as the low thermal conductivity of die-casting micro-channels and higher costs for machining micro-channels. We have already applied cold forging heatsink to cooling solutions including high-voltage inverters, wind power converters, and electric motor controllers.

1. Manufactoring process: Cold forging process

2. Material: AL1070

3. Surface treatment: Clear/black/red/gold anodizing

4. Product type: Customized Design

5. Packing: export standard carton box with pallet.

6. Application: Industry/medical/measurement/house

you have any inquiry, please contact us.

1.About the cold forging

A Forged heatsink is manufactured using a modification of this process called cold forging. Cold forging uses high pressure and low temperature to ensure that no air bubbles, or other impurities are trapped in the material. This improves the thermal properties of the heatsink, and increases the density of the material.

2.About the cold forging process

Cold forging uses a displacement process to shape the material into the desired shape. Compressive force squeezes the metal between a punch and die at room temperature until the material conforms to the die's contours. Cold forging techniques include rolling, pressing, drawing, spinning, heading, and extruding

3.The advantage of cold forging heat sink

The cold forged heat sink is widely used in the heat dissipation of LED lamps and has the following advantages:

(1) The price of cold forging die is not high, which can effectively control the cost;

(2) High production capacity, suitable for mass production;

(3) The mold production cycle is relatively short, usually 10 to 15 days;

(4) One-time molding, the heat dissipation performance of cold forging heatsink is consistent with the heat dissipation performance of the material, and the post-processing procedures are few and simple.

(5)The major advantages of cold forging are close dimensional tolerances, good surface finish quality, and the use of lower cost materials to obtain the required strength by work hardening without requiring heat treatment.

Fodor is the leading heat sink manufacturer in China, provides heat sinks and cold plates and offer customized cold forging heat sink and the other heat sink, for example, aluminum profile heat sink,skived heat sink,die casting heat sink,cold plate, if you need any heat sink, please contact fodor .