Add to Cart

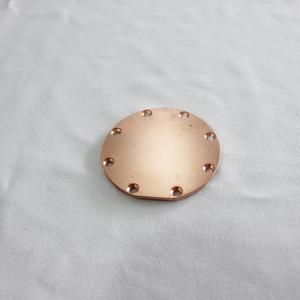

Copper Round Skived Thin Fin Heat Sink Of CNC Shovel Fins With ISO9001

Quick Detail

| Raw Material | copper |

| Custom Service | Yes, OEM/ODM Service |

| Quality System | ISO9001:2015 |

| Processing Technology | CNC Gear /Wood machining/CNC/Riveting |

| Surface treatment | clean |

| Packing Way | Blister packaging or special packing you would like |

| Application Scenario | Electronic equipment heat sink |

| MOQ Request | 100/500/1000 |

Description

Skived heat sinks are manufactured by peeling fins from a bar of solid copper or aluminum, using a sharp and accurately controlled blade tool. The tool shaves a small thickness of the material, lifts it up and bends it vertically to form the fin

Notes

This is a skived fin heat sink

Skived Fin Heat Sinks offer highly optimized cooling as they allow for higher fin densities than what is manufacturable using extrusion methodologies, but do not have an interface joint that restricts heat flow like bonded or brazed fin heat sinks. Unlike bonded or brazed heat sinks, Skived Fin Heat Sinks are constructed from a single piece of material and offer reduced thermal resistance since there is no joint between a base and fins. These heat sinks are manufactured by precisely slicing the top of the base, called skiving, folding it back to where it is perpendicular to the base, and repeating at regular intervals to create fins.

The skiving process enables high fin density and thin fin heat sink geometries for optimal thermal performance. By packing as much fin surface area into a given volume, skived fin heat sinks have greater heat transfer than other single piece construction heat sinks such as extruded aluminum heat sinks. Compared to extruded aluminum, skived fin heat sink fabrication does not rely on expensive tooling, providing greater design flexibility and faster prototyping. Instead, each fin is cut separately using the same tool which allows for lower tooling costs. This enables Fodor Technology to fully customize skived fin components for your product, which also includes liquid cooling applications.

Skived heat sinks can be constructed of aluminum or copper allowing for full, one-piece copper solutions for high performance cooling. Fodor's standard copper skived fin heat sinks are available with Shurlock pin attachments for reliable mounting and easy assembly.

For rapid thermal modeling and comparison of multiple heat sink constructions please try Genie our heat sink design tool.

Fodor can offer copper skived fi heat sink and aluminum(AL1050/6063) skived fin heat sink.