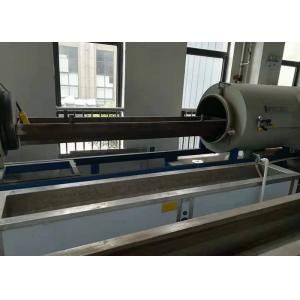

Spinning Nozzle Vacuum Chamber Furnace Stainless Steel 500*1400mm

Add to Cart

spinning nozzle cleaning machine fluidized bed vacuum cleaning furnace Vacuum Cleaning Furnace

Application

| Inner chamber size | 500*1400 mm |

| Parts size | P170mm*40mm |

| Guard(mm) | 600*2300 |

| Dimension (mm) | 4950*1600*2700 |

| Heating power | 24Kw |

| Vacuum pump | 2.35KW |

| Inner chamber size | Cleaned parts | Parts size | Quantity of parts | |

| 1 | 500*1400mm | spinneerets | P170mm*40mm | 12pcs |

| 2 | P600*1400mm(clean one kind parts at a time ,not all) | spinneerets | 360*175*75mm | 6pcs |

| spinneerets | 360*185*135mm | 6pcs | ||

| spinneerets | 310*120*40mm | 6pcs | ||

| spinneerets | 305*120*25mm | 6pcs | ||

| Screw | P35*960mm | 3pcs | ||

| 3 | P550*5000mm | Screw | P111*4700mm | 2pcs |

Vacuum cleaning furnace equipment structure

Vacuum cleaning furnace includes vacuum cleaning furnace body, furnace cover and the waste collection system, vacuum system, sealing system, electric heating system controlled by microcomputer, water cooling system and cleaning material loading and unloading system.

The working principle of

The use of chemical fiber polymer in the vacuum state of isolation of air and about 500℃ under the principle of cracking.

| Type | Model | Guard size (mm) (L*W*H) | External size (mm) (L*W*H) | Power (KW) Heat/vacuum mercury | Water consumption (m3 /h) |

Vertical type | HHM | φ500×600 | 2000×1800×2100 | 18/2.2 | 0.23 |

| HHM | φ600×800 | 2200×2000×2200 | 21/2.2 | 0.23 | |

| HHM | φ800×1000 | 2600×2300×2500 | 27/3 | 0.28 | |

| HHM | φ1000×1200 | 2800×2500×2700 | 32/2.2 | 0.45 | |

Well type | HHM | 1400×400×400 | 1600×1200×1000 | 21/2.2 | 0.28 |

| HHM | 2200×600×600 | 1800×1300×1100 | 27/3 | 0.28 | |

| HHM | 3200×600×600 | 2100×1500×1300 | 32/3 | 0.28 | |

| HHM | 4000×600×600 | 2100×1500×1600 | 36/4 | 0.45 | |

Horizontal type | HHM | φ500×600 | 2000×1000×1300 | 18/2.2 | 0.23 |

| HHM | φ600×900 | 2400×1100×1600 | 21/2.2 | 0.23 | |

| HHM | φ800×1100 | 2600×1200×1800 | 27/3 | 0.28 | |

| HHM | φ1000×1500 | 2800×1400×2000 | 32/4 | 0.45 |

advantages

It has the advantages of low pollution to the environment, clean surface of the cleaning spinneret board, smooth hole, and can prolong the service life of the spinneret board and short working time, energy saving, simple operation, good cleaning effect, high degree of automation.

Apply to industry

The vacuum cleaning furnace is used to clean the common spinnerets, special-shaped spinnerets, fine denier spinnerets and component shells in polyester, polypropylene and non-woven industries of chemical fiber industry, as well as filter elements.

FAQ

1. Q:How long will your engineer reach our factory?

A:Within one week after everything ready (machine arrival your factory, non woven material, power source, air compressor etc.Prepared)

2. Q:Does your engineer understand English?

A:Our engineers understand a little English. All our engineers have more than five years machine installation experience.

3. Q:What should we charge for your engineer?

A:You should charge for the cost of our engineer's air tickets, hotel, food, and also their salary 800CNY one day per person.

4. Q:How many days it will take for the intallation?

A: It will take around 45 days, depends on the machine type.

5. Q:How do we solve the machine problem after your engineer leaving?

A:Generally speaking, there will be no problem after finishing installation. In case you have any problem, you can contact our sales at any time. Our engineers will take a solution video according your description.