Add to Cart

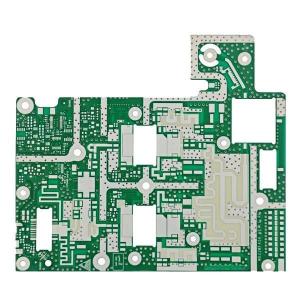

Green Solder Mask High Frequency Circuit Board ARLON FR4 2.0mm 2oz

High Frequency PCB Four Layer High Frequency Prined Circuit Board Green Solder Mask Four Layer PCB Board

Four Layer High Frequency Prined Circuit Board

High-frequency PCBs usually provide a frequency range from 500MHz

to 2 GHz, which can meet the needs of high-speed PCB designs,

microwave, radio frequency, and mobile applications. When the

frequency is above 1 GHz, we can define it as high frequency.

The complexity of electronic components and switches is continually

increasing nowadays and need faster signal flow rates. So, higher

transmission frequencies are required. High-frequency PCBs help a

lot when integrating special signal requirements into electronic

components and products with advantages like high efficiency, and

fast speed, lower attenuation, and constant dielectric properties.

High Frequency (HF) PCB is used to transmit electromagnetic waves

in the frequency of GHz with minimal loses in the variety of

applications, including mobile, microwave, radio frequency (RF) and

high-speed design applications. Hence, printed circuit boards with

some specific characteristics are used to transmit these

electromagnetic waves. Several parameters are taken into

considerations while designing a PCB for high frequency

applications.

A high frequency PCB can meet your needs when incorporating a

special signal requirement into your electronic devices and

products. These higher transmission frequencies are capable of

supporting the faster signal flow rates that are a necessity in

today’s increasingly complex electronic switches and other

components.

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 2- 24layers |

| Material | ROGERS, TACONIC, ARLON, FR4, |

| Board Size | Min 5mm x 5mm | Max 500mm x 745mm |

| Board Thickness | 0.2mm - 4.0mm |

| Copper Weight(Finished) | 0.5oz - 2oz |

| Min Tracing/Spacing | 3mil/3mil |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow... |

| Silkscreen Color | White, Black, Yellow... |

| Surface Finish | Electroless nickel/immersion gold (ENIG) - RoHS |

| Immersion silver - RoHS | |

| Immersion tin - RoHS | |

| Min Annular Ring | 0.1mm |

| Min Drilling Hole Diameter | 0.15mm |

| Other Techniques | Peelable solder mask |

| Gold fingers | |

| Carbon oil | |

| Countersink holes |

FAQ:

Q1:Could you provide PCB Assembly services and components sourcing?

A: Yes, we could also provide components sourcing and PCB Assembly

services as well as box build if request.

Q2:Which countries have you worked with?

A:USA, Canada, Italy, Germany, UK, Spain, France, Russia, Iran,

Turkey, Czech Republic,Austria, Australia, Brazil, Japan, India

etc.

Q3:Are my PCB files safe when I submit them to you for

manufacturing?

A: We respect customer's copyright and will never manufacture PCB

for someone else with your files unless we receive written

permission from your side, nor we'll share these files with any

other 3rd parties. And we could sign NDA with client if necessary.

Q4:If we have no PCB file/Gerber file, only have the PCB sample,can

you produce it for me?

A: Yes,we could help you to clone the PCB. Just send the sample PCB

to us, we could clone the PCB design and work out it.

Q5:What is your standard lead time for PCB?

A: Sample/prototype(less than 3sqm):

1-2 Layers: 3 to 5working days (fastest 24hours for quick turn

services)

4-8 Layers: 7~12 working days (fastest 48hours for quick turn

services)

Mass production (less than 200sqm):

1-2 Layers:7 to 12 working days

4-8 Layers:10 to 15 working days