Finishing Carbide Hob Sliver Grey Non Involute Worm Gear Hob Cutter

Brand Name:AOJIA

Certification:ISO

Minimum Order Quantity:negotiation

Delivery Time:within 10 working days

Payment Terms:L/C

Place of Origin:CHINA

Contact Now

Add to Cart

Site Member

Location:

Zhuzhou Hunan China

Address:

Jinshan Industrial Park, Hetang District, Zhuzhou City, Hunan Province, China

Supplier`s last login times:

within 14 hours

Product Details

Company Profile

Product Details

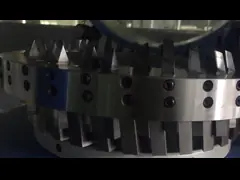

Carbide Hobbing Cutter Spot Goods And High Accuracy

- Gear machining tools with teeth arranged in a spiral line along a cylinder or a cone are used to process cylindrical gears, worm gears and other cylindrical toothed workpieces (see gear machining, gears) according to the generating method. According to different uses, the hob is divided into gear hob, worm gear hob, non-involute hob and custom hob.

- The gear hob is a tool that cuts gears by the generating method according to the meshing principle of the helical gear pair. The gear hob is equivalent to a small gear, and the cut gear is equivalent to a large gear. The gear hob is a helical gear with a large helix angle β0 and a small number of thread heads (1 to 3 teeth), the teeth are very long, and the hob can index the cylinder for many turns, so that the helix angle γz is very high. Small worm too. In order to form the cutting edge, several chip grooves are milled along the axis on the end face of the worm to form the front and rake angles; after the shovel teeth and shovel grinding, the flank and the clearance angle are formed. The cutting edges on both sides of the gear hob are the intersection lines of the front and the surface of the side shovel, which should be distributed on the helical surface of the worm, which is called the basic worm of the hob.

| Specification | Outer diameter×length×inner hole |

| M0.5 a20º A | Ø50×40×22 |

| M0.6 a20º A | Ø50×40×22 |

| M0.65 a20º A | Ø50×40×22 |

| M0.7 a20º A | Ø50×40×22 |

| M0.8 a20º A | Ø50×40×22 |

| M0.9 a20º A | Ø50×40×22 |

| M1 a20º A | Ø50×40×22 |

| M1.25 a20º A | Ø50×40×22 |

| M1.5 a20º A | Ø55×45×22 |

| M1.75 a20º A | Ø55×45×22 |

| M2 a20º A | Ø55×50×22 |

| M2.25 a20º A | Ø60×50×22 |

| M2.5 a20º A | Ø65×55×22 |

| M2.75 a20º A | Ø65×55×22 |

| M3 a20º A | Ø70×60×27 |

| M3.35 a20º A | Ø75×65×27 |

| M3.5 a20º A | Ø75×70×27 |

| M3.75 a20º A | Ø80×70×27 |

| M3short teeth a20º A | Ø70×60×27 |

| M3double head a20ºA | Ø80×80×32 |

| M4 a20º A | Ø80×75×27 |

| M4.25 a20º A | Ø85×80×27 |

| M4.5 a20º A | Ø85×80×27 |

| M5 a20º A | Ø90×90×27 |

Finishing Carbide Hob Sliver Grey Non Involute Worm Gear Hob Cutter

Inquiry Cart

0