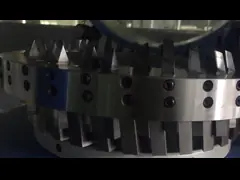

Solid Carbide Gear Hob Cutters Tool Golden Color Ti-Al-XN coating

Add to Cart

Solid Carbide Gear Hob Cutters

Coated tools have become the symbol of modern cutting tools, and the proportion of use in tools has exceeded 50%. Various tools used in cutting, including turning tools, boring tools, drills, reamers, broaches, taps, thread combs, rolling heads, milling cutters, forming tools, gear hob and gear shapers, etc. A coating process is used to improve their performance.

category

There are four types of coated knives: coated high-speed steel

knives, coated carbide knives, and coated knives on ceramic and

superhard material (diamond or cubic boron nitride) inserts. But

the former two types of coated knives are used the most. The

coating on ceramic and superhard material inserts is a material

with a lower hardness than the substrate. The purpose is to improve

the fracture toughness of the insert surface (can be increased by

more than 10%), reduce the chipping and breakage of the insert, and

expand the scope of application.

New coating technology

The new Ti-Al-XN coating technology is to use vapor deposition

method to coat the surface of high-strength tool substrate with a

few microns of high hardness and high wear resistance refractory

Ti-Al-XN coating, so as to reduce tool wear and prolong life. The

purpose of increasing cutting speed. It is an important achievement

achieved by the national major special project of high-end CNC

machine tools and basic manufacturing equipment.

| Table of carbide hob coating types | |||||||

| No | coating material | hardness(HV) | Coefficient of friction for steel (dryness) | Internal stress(Gpa) | Maximum applicable temperature (Celsius) | The color of the coating | coating structure |

| 1 | TIN | 2300 | 0.4 | -2.5 | 600 | golden | monolayer |

| 2 | AlCrN | 3200 | 0.35 | -3 | 1100 | blue grey | monolayer |

| 3 | TiCN | 3000 | 0.4 | -4 | 400 | blue grey | multilayer |

| 4 | WC/C | 1000/2000 | 0.10-0.20 | -1 | 300 | Black gray | laminal |

| 5 | CrN | 1750 | 0.5 | 0.75 | 700 | silver gray | monolayer |

| 6 | polycrystalline diamond | 8000-10000 | 0.15-0.20 | 600 | LightGray | monolayer | |

| 7 | iAlN | 3300 | 0.30-0.35 | 0.866666667 | 900 | Purple-grey | Nano-structure |

| 8 | TiCN+TiN | 3000 | 0.4 | -4 | 400 | golden | Multi-layered, sloping |

| 9 | TiAlN+ WC/C | 3000 | 0.15-0.20 | 0.85 | 800 | LightGray | multilayer,laminal |

| 10 | DLC(a-C:H) | 2500 | 0.10-0.20 | 350 | Black gray | monolayer | |

| 11 | TiAlN | 3300 | 0.25 | -0.866666667 | 900 | Purple-grey | Nano-structure |

| 12 | TiAlN | 3300 | 0.4 | 0.857142857 | 900 | blue grey | Nano-structure |

| 13 | TiAlN | 3500 | 0.4 | -4 | 800 | Purple-grey | monolayer |