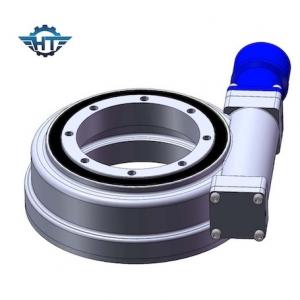

SE3 Worm Gear Drive PV System Galvanizing 1500NM Tilting Torque

Add to Cart

SE3 Hourglass Worm Gear Drive For PV Power Sun Tracking Solar Panel System

Worm Gear Slewing Drive Description

As technology has improved, more slewing drives are using hourglass worm technology, in which the worm is shaped to engage more teeth in the gear, thus the torque imporved and the backlash decreased.

This increased tooth engagement results in greater strength,

efficiency and durability.The slewing drive uses standard worm

technology in which the worm on the horizontal, the speed ratio of

the shaft depends on the relationship between the number of threads

on the worm and the number of teeth in the worm gear.

How to install the slewing drives?

1. Clean the mounting structure, e.g. from welding, galvanizing, residues, dirt, etc.

2. Lift the slew drive with eye bolts.

3. The slew drive shall be mounted in unloaded condition.

4. The following procedure shall be followed in order to avoid deviations between bolt tightening forces.

5. Apply thread lock liquid to threads.

6. Lay thread lock liquid on thread gap requesting fitting parts fully.

7. Preload the bolts crosswise. See the general pattern in sketch below of how bolts get torque in crosswise sequence. Start with either inner or outer ring. Do the crosswise torqueing of all bolts to 30% of tightening torque. Then repeat crosswise torque to 80% of tightening torque. Finally crosswise torque to 100% of the tightening torque.

Performance Parameters of SE series

| SE Model Performance Parameters | ||||||||||||

| Model | Rated Output Torque (N.m) | Tilting Torque (N.m) | Holding Torque (N.m) | Axial Load (kN) | Radial Load (kN) | Ratio | Efficiency | Precision (degree) | IP | Working Tep. (℃) | Self- locking | Weight (kg) |

| 1" | 400 | 1000 | 1800 | 22 | 12 | 32:1 | 40% | ≤0.1 | 66 | -40~+120 | Yes | 6 |

| 3" | 600 | 1500 | 3000 | 30 | 16 | 31:1 | 40% | ≤0.1 | 66 | -40~+120 | Yes | 8 |

| 5" | 800 | 6000 | 9200 | 68 | 27 | 37:1 | 40% | ≤0.1 | 66 | -40~+120 | Yes | 12 |

| 7" | 2000 | 13500 | 13200 | 132 | 58 | 57:1 | 40% | ≤0.1 | 66 | -40~+120 | Yes | 21 |

| 9" | 4400 | 45000 | 30800 | 340 | 130 | 61:1 | 40% | ≤0.1 | 66 | -40~+120 | Yes | 49 |

| 12" | 5800 | 54400 | 40560 | 480 | 190 | 78:1 | 40% | ≤0.1 | 66 | -40~+120 | Yes | 61 |

| 14" | 6550 | 68000 | 54200 | 680 | 230 | 85:1 | 40% | ≤0.1 | 66 | -40~+120 | Yes | 63 |

| 17" | 9400 | 135600 | 65040 | 980 | 390 | 102:1 | 40% | ≤0.1 | 66 | -40~+120 | Yes | 105 |

| 21" | 16000 | 203400 | 81000 | 1600 | 640 | 125:1 | 40% | ≤0.1 | 66 | -40~+120 | Yes | 149 |

| 25" | 21000 | 271160 | 89000 | 2400 | 950 | 150:1 | 40% | ≤0.1 | 66 | -40~+120 | Yes | 204 |

Applications

There are many applications where a rotary drive can be used,

primary because it is well suited for applications that require

load to maintain power and rotational torque.

Slewing drives are widely used in aerospace area, solar power

systems, wind turbines, satellite broadcasting system, and

engineering machinery like truck cranes, and man lifts, etc.

Recently years, it has been prosperously used in photovoltaic power

generation systems, special vehicle, heavy-duty flat-panel truck,

container cranes, truck mounted crane, automobile crane and aerial

vehicles, cranes, gantry cranes, small wind power stations, space

communications, satellite receiver, etc.