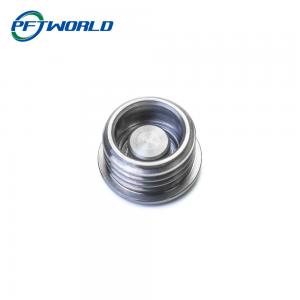

Stainless Steel Machining High Precision Copper Brass Aluminum CNC Milling parts

Add to Cart

Stainless Steel Machining High Precision Copper Brass Aluminum CNC Milling parts

About us:

Shenzhen Perfect Precision Products Co., Ltd. is a national high-tech enterprise manufacturing precision parts, using the latest CNC turning, CNC milling, multi-axis turning, milling compound, injection molding, sheet metal, and other processes.

Professional supply of various materials and different special processing of high-quality components. With over 15 years of rich experience, we are proud to work with customers from different fields to establish close cooperation and provide customers with first-class products and services.

Our company has advanced imported CNC equipment, such as HAAS Machining Center of the United States (including five-axis linkage), Japanese CITIZEN/TSUGAMI (six-axis) precision turning and milling compound machine, HEXAGON automatic three coordinates, etc., the production of a complete range of parts widely used in aerospace, automotive, medical, optics, instrumentation, ocean and many other fields.

We have an experienced engineering team, passed the ISO9001/ISO13485/AS9000/IATF16949, etc

System certification at the same time also implemented factory digitization, such as ERP/MES system, to further improve the guarantee from sample manufacturing to mass production.

Perfect always adheres to the pursuit of perfect quality as the goal, with domestic and foreign customers highly recognized and consistent praise.

Turning Features:

Turning is a method of cutting a workpiece on a lathe using the rotation of the workpiece relative to the tool. Turning is the most basic and common cutting method. Most workpieces with revolving surfaces can be processed by turning methods, such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, grooves, threads, and rotary forming surfaces. Common lathes can be divided into horizontal lathes, floor lathes, vertical lathes, turret lathes and profiling lathes, most of which are horizontal lathes.

Product Qualification

CNC Turning Machine: Miyano, TSUGAMI, ASD, CITIZEN, Helong, HAAS

Quality Assurance: ISO9001:2015, SGS, RoHS, TUV

Product advantages

1. Import raw materials, Stable and Durable - Ball screw adopts imported bearing steel, high hardness, high precision, strong and durable.

2. Fine workmanship, Focus on details - Pay attention to detail trimming, reject burrs and unevenness, and make installation more convenient.

3. Forward and reverse rotation, Sliding smoothly - Can provide left and right rotating docking, beautiful and generous, high-precision positioning.

Specification of CNC Machining Parts

| Material available | Stainless steel, aluminum, brass, Plastic(ABS,POM,PC(PolyCarbonate),PC+GF,PA(nylon), PA+GF, PMMA(acrylic)PEEK, PEI etc), |

| Process | CNC machining(turning, milling, ) |

| Surface treatment: | Polishing, sandblasting, anodizing, brushing, powder coating, electroplating, zinc plating, silk-screen |

| Application | for a new project to be tested |

| Quality control | ISO9001:2008 certificated |

| Drawing format: | PDF/DWG/IGS/STP. |

| Experience | 16 years of professional manufacturing |

| Our Advantage | Superior in quality, reasonable in price and deliver on time |

| Packaging | Wood case or carton box, 1, With plastic bag, with the pearl-cotton package. 2, To be packed in cartons or wooden cases. 3, Use glue tape to seal cartons. or pin tight the wood case with nail. 4, Deliver out by DHL, FEDEX. Or according to customers' requirements. |

| Lead time | Normally 3~7 days,but some of them depend on the quantities request. |

| Delivery: | By DHL, FEDEX, Shipping |

FAQ

Q1:Where can I get product&price information?

A1:Send us an e-mail, we will contact you as we receive your mail.

Q2: How soon can I get samples?

A2: Depending on your specific project, it usually takes 10 to 20 days.

Q3:How to enjoy the OEM services?

A3:Usually, based on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q4:Can you make machining parts based on our samples?

A4:Yes, we can make measurements based on your samples to make drawings for

machining parts making.

Q5: What is the payment terms? Do I pay first or after the items have been delivered?

A5:The payment methods are T/T,Western Uinion and Alibaba trade assurance.

30% Deposit before production, the balance before delivery. (when we finished the products,we will send the digital photo from different angle for your confirmation.after you confirmed,you can pay the balance,and we will deliver the goods).