NOBO Bedding Spring Making Machine Electronic Screen Control

Brand Name:NOBO

Certification:CE

Model Number:NB-120

Minimum Order Quantity:1Sets

Delivery Time:15-45 work days

Payment Terms:T/T, L/C

Contact Now

Add to Cart

Site Member

Location:

Foshan Guangdong China

Address:

RM A038, 14FL , SHIBO FINANCIAL CENTRE , KUIQI RD ,FOSHAN , GUANGDONG ,CHINA

Supplier`s last login times:

within 27 hours

Product Details

Company Profile

Product Details

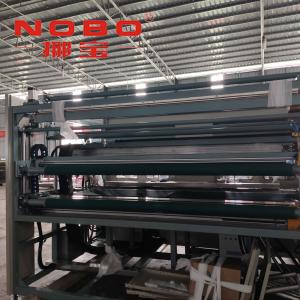

High And New Technology Products bedding Springs Making Machinery

Automatic spring bed net production line

High And New Technology Products Bedding Springs Making Machinery

NB-120 latest model for producing "Bonell" type innerspring units. It can produce innerspring units

directly from wire.Firstly the steel wire is coiled to a spring, and then transferred and inserted to the

assembler by the automatic feeding system.

Adopt Imported Glue Tank and Servo Control System for Pushing Feeding Spring Rows

Application

Adapt to cylindrical and barrel shape springs

The heat-treatment device can adapt to different spring height,

easy for adjustment

The non-woven feeder system, save material and labor

Multiple fault detecting device, effectively reduced the wastage

Use semi-automatic coiling head, faster than normal coiling head

Special protective device

Main business:

Mattress spring making machine ,spring assembling machine,

Conjoined coiling machine, Automatic

mattress spring making machine , Tape edge machine , Packing machine

Ce certificate: Spring Makiing Machine & String Spring Machine

Package&Shipping:

You can just tell us your needs and we will arrange everything from the initial consultaion to the delivery

of your chosen port anywhere in the world timely. All of our produrts are well packed to ensure the safety

of the products.

Packaging | |

Size | (L) * (W) * (D)mm |

Weight | *kg |

Packaging Details | The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

FAQ:

1. who are we?

We are based in Guangdong, China, start from 2013,sell to Northern Europe(10.00%),Eastern Asia(10.00%),

Mid East(10.00%),Africa(10.00%),Southeast Asia(10.00%),Eastern Europe(10.00%),South America(10.00%),

North America(10.00%),South Asia(5.00%),Southern Europe(5.00%),Western Europe(5.00%),Central

America(5.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Automatic bunch of spring machine,Bonnell spring coiling machine,Mattress Border Frame Wire Bending,

Automatic Coiler Machine,Automatic side seamer of the bed cushion

4. why should you buy from us not from other suppliers?

We have 7 years production experience for mattress machine. In order to meet the market demand customer

need in accordance with special requirements of custom-made

mattress production facilities.

5. what services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,D/P D/A;

Language Spoken:English,Spanish,Chinese

NOBO Bedding Spring Making Machine Electronic Screen Control

Inquiry Cart

0