Add to Cart

PET Plastic Packing Belt Double Output Making Machine

PET Packing Strap Production Line

Process Flow of PET Packing Strap Production Line:

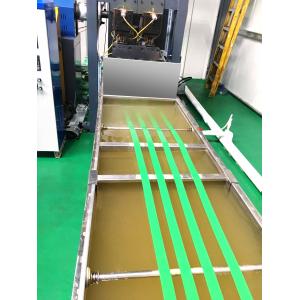

①Material→②Stirring raw material→③Pre crystallization drying→④vacuum dehumidification→⑤Extruding→⑥cooling and forming →⑦ oven preheating →⑧ primary stretching →⑨secondary stretching →⑩ embossing → ⑪shaping→⑫ cooling→ ⑬winding

Machine Description:

PET Strap Making Machine is using pet bottle flakes, to produce

various specifications of pet strap.

PET Packing Strap Production Line Details:

| No. | Name | Qty |

| 1 | Dehumidifying and Crystallizing Unit | 1 set |

| 2 | Oil and dust filter | 1 set |

| 3 | Single Screw Extruder | 1 set |

| 4 | Single Cylinder Filter | 1 set |

| 5 | Melt Pump | 1 set |

| 6 | Die Head | 1 set |

| 7 | Cooling Water Tank | 1 set |

| 8 | Stretching Oven | 1 set |

| 9 | Five Roller Gearbox | 3 sets |

| 10 | PLC Control System | 1 set |

| 11 | First and Second Stretching Rollers | 1 set |

| 12 | Shaping Oven | 1 set |

| 13 | Five-roller Haul-off Device | 1 set |

| 14 | Fourth Haul-off Rollers | 1 set |

| 15 | Winder | 2 sets |

1. Extruder

---Specially designed screw and barrel for different materials

--- Candle type filter, bigger filtering area, longer working time, no need change filters shortly.

----Close--loop control system from extruder to melt pump, by which

extrusion can be automatically controlled by melt pump.

----Melt pump ensures stable extrusion

---304 stainless steel water cooling tank

3. Extrusion Mold

--- Good quality and special treatment

----Produce different sizes of strpas.

----1-6 straps extruding, according to customer request and straps

size.

4. Hual-off Rollers

----Gear transmission

----Chromed rollers

5. Shaping Oven

Parameters of PET 1 to 2 production machine:

| Item | JTPET-90 |

| Screw design | Single screw |

| Straps Qty. | 2 straps |

| Output/Day | 5.5-6T/24 hours |

| Screw Dia. | 90mm |

| Winder Qty. | 2 sets |

| Material used | 100% Recycled Bottle Flakes/Virgin Material/mixed with |

| Running power | 110-120kw |

| Installed power | 200kw |

| Strap specifications | Width 9-32mm thickness 0.6-1.2mm |

| Workshop area | L (55m) ×W (2m) ×H (7m) |

| Electric components | Schneider |

| Materials | PET raw material or 100% PET bottle flakes recycled |

Final Products of PET Strap Band/Belt Extrusion Line/ PET Strap Band/Belt Extrusion Machine

Features of PET Strap Making Machine:

1.Screw with compression ratio especially for PP/PET, gradually

changing diameter and deeper thread groove at the melting part.

2. Gearbox with hardened gears; Die can be precisely adjusted to ensure stable production and smooth surface of straps.

3.Precise dosing and raw material mixing.

4.Preheat and dry circulating automatically.

5.Even plasticization, stable extrusion and accurate temperature

control.

6.Big hauling force stretching device and isolated heating oven.

7.Large capacity stainless steel water tank, automatic liquid level

control.

Advantages for PET Strap Making Machine:

Special twin screw extrusion technology and single screw extrusion technology can be choosing as per customer needs.

Process 100% recycled PP/PET bottle flakes or pellets.

Even plasticization and stable extrusion with PLC automatic control for the full line.

Melt pump ensure continuously stable producing.

1-6 straps extruding, according to customer request and straps size.

Machine Products Description:

Applications: widely used in steel, chemical industry, aluminum,

paper making, brick kiln, tobacco, electronics, textile and timber

industries.

Package and Delivery:

Service and Support:

1. Pre-sales Service:

* Showing the production video

* Supply the FAQ questions

* Project evaluation

* Marketing trends analysis

* Showing our customer's factory in local

* Visit our company

2. During-manufacturing

* Provide layout and engineering condition

* Inform the schedule of production

* Test machine before shipment

* Sending photos before loading

3. After-sales Service

* Overseas installation

* Training the workers

* Build customer database to tracking machine conditions

* Space parts supply in soonest time

* Visit customer and solve the problems they have

* Teach the products care and maintenance skills

FAQ:

Q: Is your company factory or trade company?

A: we are factory, we are engaged in this business for 20 years, we

also have our own PET straps factory.

Q: Can you guarantee your quality?

A: Of course. We are the manufacture factory. More importantly, we

put a high value on our reputation. Best quality is our principle

all the time. You can be assured on our production completely.

Q: What is the payment term?

A: The best way for both of us is 30% T/T deposit and 70% T/T

balance payment before shipping, since we will test the machine

before shipping. Of course, you can choose the way that more

convenient (Payment terms: T/T, L/C, Western Union etc.)

Company Profile:

Shenzhen Jiatuo Plastic Machinery Co., Ltd, specilizing in PP & PET Strap production and development for more than 20years.

Products consist of PET/PP Strap Making Machine, Rattan Making Machine, Handheld Strapping Machine, Plastic Coating Machine, high-precision Plastic Embossing Roller, PP & PET Strap Winder, Tensile Testing Machine, Strap Printing Machine, Plastic Extrusion Screen Changer, Extrusion Machine Parts, automatic suction machine, screw feeder, crusher, etc; Automatic wrapping machine, automatic packing machine, automatic packing machine for all bags and automatic packing machine; High grade, high-strength and environment-friendly PP machine, PP packing belt, pet plastic steel belt and other packaging materials.

The target of Jiatuo Machinery Co., Ltd. is to offer the best

quality machines to the customers from all over the world. With the

advanced technology, experienced engineers and skilled workers, we

have the capability to manufacture specific machines according to

customer's requirement.

Excellent quality and professional service is the promise made by

Jiatuo Machinery Co., Ltd. to new and old friends.

We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!