Product Details

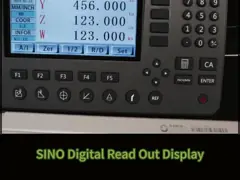

SINO SDS 2MS Digital Readout 2 Axis With Linear Magnetic Scale Dro

Kit For Milling Machines

The Sino SDS2MS DRO is a sophisticated digital display gauge

designed for lathe and milling machines. It provides a variety of

functions that can be easily customized to accommodate different

machine tools.

Key Features:

1. Versatile functionality: The SDS2MS DRO supports radius/diameter

conversion, MM/Inch conversion, and absolute/relative conversion,

providing enhanced flexibility for measurements and calculations.

2. Enhanced precision: The mid-splitting function of the DRO allows

for precise positioning and measurement of workpieces. The

convenient "R" function simplifies radius calculations, while the

smooth "R" function ensures seamless operation during machining

processes.

3. Convenient memory storage: The DRO features a built-in memory

capable of storing up to 200 sets of zero positions, making it easy

to recall previous settings and enhance workflow efficiency.

Specifications:

- Voltage range: AC 85V~250V / 50Hz~60Hz

- Power consumption: 15W (25VA)

- Coordinate options: Single coordinate, two coordinates, three

coordinates

- Display type: Seven-segment display with eight-digit characters

showing symbols (for two or three axes)

- Net weight: 1.3kg (2.9lb)

- Input signal compatibility: TTL, EIA-422 open collector output

signal, compatible with programmable controllers

- Input signal frequency support: >100 KHz

- Resolution options: 10 microns, 5 microns, 2 microns, 1 micron, 0.5

microns

Additional Features:

1. The robust design and professional software guarantee reliable

performance and long-lasting durability.

2. Enhanced anti-interference capabilities ensure compliance with

advanced EMC testing standards.

3. The DRO is designed to adapt to a variety of processing

environments, making it ideal for a wide range of applications.

Experience the precision and convenience of the Sino SDS2MS DRO

Digital Readout System for your lathe or milling machine today!

The SDS2MS DRO is a multifunctional, two-coordinate numerical

display gauge. By adjusting the parameters based on the machine

tool, this gauge can be easily customized to suit the specific

function needed.

Upgraded Functions:

- Radius/diameter conversion: Seamlessly switch between radius and

diameter measurements.

- MM/Inch conversion: Easily toggle between metric (mm) and imperial

(inch) units.

- Absolute/relative conversion: Switch between absolute and relative

positioning for versatile measurements.

- Mid-splitting function: Enables precise positioning by splitting

the workpiece in half.

- Easy "R" function: Simplifies radius calculations for improved

accuracy.

- Smooth "R" function: Ensures smooth, continuous operation during

machining for better results.

- PCD hole positioning on circumference: Accurate positioning for

holes on the circumference of a circle, perfect for drilling

applications.

- 200 groups zero position memory: Store up to 200 zero positions for

quick recall and improved workflow efficiency.

Packaging List :

| 1 PC | 2 Axis digital readout SDS2MS |

| 1 PC | Transparent cover |

| 1 PC | Instruction Manual (English) |

| 1 PC | Cable |

Product image /photos:

The rack in the picture is optioned, not standard product.

Company Profile

Our company, Guangzhou SINO International Trade Co., Ltd is located

in Guangzhou city, Guangdong province, China. Guangzhou SINO

International Trade Co. LTD is the subsidiary of the SINO group.

SINO specializes in the development and manufacture of

high-precision measuring products since 2002. It has a series of

the world’s most advanced equipment and has been certificated by

IS09001, CE, RoHS, and the electrical safety standards for European

authentication. The competitive products linear grating ruler and

digital readout are famous in the world. With untiring efforts in

development in this area since 1989, the best seller in China for

the last ten years.

SINO is the leading linear encoder & DRO manufacturer in China. Our

main products included linear scales encoder, magnetic encoder,

angle encoder, and DRO displays suitable for milling, lathe, EDM,

grinding machine, boring machine and we keep developing and

improving to move forward with very good quality. The company has

cooperated with many clients from overseas and has obtained

consistently high praise from our customers since it was set up.

The company tries its best to do well at any aspect from each

stitch, each point of procedure of manufacturing to final

inspection, packing, and shipment. We insist on the principle of

development of 'All we do are clients need' to provide you with excellent service of processing! We sincerely

welcome you to visit our company or contact us for cooperation.