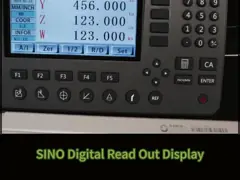

3 Axis DRO Kit SINO SDS6-3V Digital Readout System With Linear Scale TTL Signal Output For Lathe Machine

Brand Name:SINO

Certification:CE,RoHS

Model Number:SDS2-3VA, KA-300*2

Minimum Order Quantity:1 set

Delivery Time:5-8 days

Payment Terms:T/T, L/C

Contact Now

Add to Cart

Verified Supplier

Location:

Guangzhou China

Address:

401, No.7, 1st Street, Zone 3 Xilang East-west Road, Liwan District, Guangzhou

Supplier`s last login times:

within 24 hours

Product Details

Company Profile

Product Details

3 Axis DRO Kit SINO SDS6-3V Digital Readout System With Linear Scale TTL Signal Output For Lathe Machine

The DRO system is specifically tailored for 2-axis mills.

It features a TFT display DRO system, the SDS2-3VA, and comes with two standard grating rulers, the KA-300.

Package list:

| Item name | 2 axes TFT milling machine DRO system |

| Digital Readout (DRO) | SDS2-3VA |

| Linear scale for axis X | 670-1020mm |

| Linear scale for axis Y | 370-570mm |

| Rack for DRO | L400 |

| Protection cover for X scale | Type C |

| Protection cover for Y scale | Type D |

| Bracket for scales | T-bracket (1 set) |

| Others | Cable / Screws / Manual |

Functions for milling machine:

- Midsplit: Symmetrical division or balancing of parts.

- Simple “R”: Basic radius or rounded edge calculation.

- Oblique Line Hole Positioning: Accurate placement of holes along angled lines.

- PCD Circle Equally Dividing: Evenly spacing points around a circle based on Pitch Circle Diameter.

- Bevel Processing: Machining or finishing angled edges or surfaces.

Detail Information:

Pin Description:

All linear scales were tested before delivery. Here is a sample of a scale's test report.

3 Axis DRO Kit SINO SDS6-3V Digital Readout System With Linear Scale TTL Signal Output For Lathe Machine

Inquiry Cart

0