SINO SDS2-3MS Digital Readout System With 3- Coordinate Numerical Display For Lathe And Milling Machines

Add to Cart

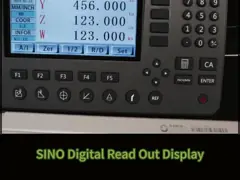

SINO SDS2-3MS Lathe Milling Machine with DRO Digital Readout SDS3MS Display

SINO SDS2-3MS Lathe Milling Machine DRO Digital Readout With Three Coordinate Numerical Display.

The SDS2-3MS SINO Lathe Milling Machine DRO Digital Readout with SDS3MS Display is a digital readout system specifically built for lathe and milling machines. It delivers accurate and real-time measurement feedback, allowing operators to precisely monitor and manage the machining process.

Features:

Multiple Axes Support:This digital readout system supports multiple axes, enabling precise measurement feedback and control across various machine movements. Machinists can achieve accurate positioning and control on multiple axes simultaneously, enhancing overall machining efficiency.

Lathe and Milling Compatibility:Designed to be compatible with both lathe and milling machines, the SDS2-3MS DRO system offers versatility for machinists working with different types of equipment. It seamlessly integrates into the control systems of these machines, facilitating streamlined operations and setup.

High Accuracy:With its high-accuracy measurement readings, the digital readout system ensures precise control over machine movements. This capability is essential for achieving tight tolerances and optimal machining results in diverse industrial applications.

Incremental and Absolute Modes:The SDS2-3MS DRO system supports both incremental and absolute measurement modes, providing flexibility for various machining scenarios. Operators can easily switch between modes as needed, adapting to different machining requirements with efficiency and accuracy.

Functionality:

The SDS2-3MS SINO Lathe Milling Machine DRO Digital Readout System enables operators to precisely monitor and control machine motions during lathe and milling operations. It delivers real-time measurement feedback, allowing operators to make necessary modifications and corrections to get the required machining output.

Usage:

Digital Readout (DRO) systems are essential tools in machining operations that demand precise measurement and control across various industries, including metalworking, woodworking, automotive, aerospace, and more.

Key Applications:

Lathe Operations:The DRO system is crucial for lathe operations such as facing, turning, tapering, threading, and grooving. It enables machinists to accurately measure and control tool movements, ensuring precise and efficient machining processes.

Milling Operations:In milling operations, including contouring, slotting, drilling, and profiling, the DRO system plays a vital role. It allows for precise measurement and control of cutter movements, enabling operators to achieve accurate and repeatable milling tasks with ease.

Versatile 3-Coordinate Numerical Display (SDS3MS):

The SDS3MS DRO system features a versatile 3-coordinate numerical display. This display can easily adapt to different machine functions by adjusting parameters, making it suitable for various machining applications across different types of equipment.

Multipurpose Functionality:With its ability to switch functions seamlessly between different machine tools, the SDS3MS DRO system enhances operational flexibility and efficiency. Machinists can rely on its accurate measurement capabilities to optimize their machining processes and achieve superior results.

SINO SDS3MS digital readout parameters

- Voltage Range: AC 85V ~ 250V, 50Hz ~ 60Hz.

- Power Consumption: 15W (25VA).

- Coordinate Number: Supports 1 coordinate, 2 coordinates, or 3 coordinates.

- Display: 7-segment display for showing signed output data with 8 characters, suitable for two or three axes.

- Weight: 2 kg.

- Input Signal: Supports TTL, EIA-422, and open collector output signals, providing convenient interfacing with programmable controllers.

- Input Signal Frequency: Allows frequencies greater than 100 kHz.

- Resolution Options: Supports resolutions of 10 microns, 5 microns, 2 microns, 1 micron, and 0.5 microns.

Basic Functions

mm/inch Transformation Absolute/relative Transformation

Mid-split Function Simple "R" Function.

Smooth "R" Function. Divide the perimeter of a circle.

Save 200 workpiece zero points. Divide holes along an oblique line.

Mathematics calculation Tool Diameter Compensation

Bevel Process Zero location autorest

| 1 PC | 3 Axis digital readout SDS3MS |

| 1 PC | Transparent cover |

| 1 PC | Instruction Manual (English) |

| 1 PC | Cable |

Product image /photos:

The rack in the picture is optioned, not standard product.