SINO KA600-1900mm Linear Scale Glass Sensor 3 Axis DRO Digital Read Out Display For CNC Milling And Lathe

Add to Cart

SINO KA600-1900mm Linear Scale Glass Sensor+DRO 3Axis Digital Read Out Display CNC Mill Lathe

Product Description:

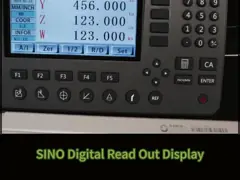

The SINO KA600-1900mm Linear Scale Glass Sensor combined with a

3-axis Digital Read Out (DRO) Display is a powerful and accurate

system designed for CNC milling and lathe machines. This package

features a high-quality linear scale glass sensor from SINO, along

with a user-friendly digital display for precise measurements and

control.

Features:

Linear Scale Glass Sensor: The KA600-1900mm linear scale glass

sensor ensures high-precision measurement of the machine's axis

position. It provides reliable and repeatable readings, allowing

for accurate machining operations.

3-Axis Digital Read Out Display: The DRO system includes a 3-axis

digital display, enabling simultaneous monitoring and control of

multiple machine axes. The display offers clear numerical readings,

making it easy for operators to make adjustments during machining.

CNC Compatibility: The SINO KA600-1900mm Linear Scale Glass Sensor

and DRO system are designed to integrate seamlessly with CNC

milling and lathe machines. They provide precise feedback and

enhance the overall machining accuracy.

User-Friendly Interface: The digital display is equipped with a

user-friendly interface, making it easy to navigate and set up the

system according to specific machining requirements. Operators can

quickly learn how to operate the DRO system effectively.

Increased Efficiency and Accuracy: By utilizing the SINO

KA600-1900mm Linear Scale Glass Sensor and DRO system, operators

can improve machining efficiency and achieve higher accuracy in

their CNC milling and lathe applications.

Package includes:

linear glass scale, 0–1900 mm, in one piece.

A 0.5/1/5um resolution is available.

Customized encoder lengths (L0) can be provided based on the needs of the customers.(Length:1000-3000mm)

The SINO KA600 linear scale is a precision measuring device commonly used in various industries, including machining, manufacturing, and metrology. It is designed to provide accurate and reliable measurements of linear displacement or position.

The operation of an absolute optical angle encoder typically involves a rotating disc or ring that contains a pattern of optical markings or codes. These markings are read by optical sensors or detectors, which convert the optical patterns into electrical signals. The electrical signals are then processed to determine the absolute angular position.

The optical markings on the encoder disc or ring can take various forms, such as binary codes, gray codes, or analog signals. The number of markings or codes determines the resolution or precision of the encoder. Higher-resolution encoders have more markings or codes, allowing for finer angular resolution.

| Model | L0 | L1 | L2 | Model | L0 | L1 | L2 |

| KA600-1000 | 1000 | 1150 | 1170 | KA600-2100 | 2100 | 2250 | 2270 |

| KA600-1100 | 1100 | 1250 | 1270 | KA600-2200 | 2200 | 2350 | 2370 |

| KA600-1200 | 1200 | 1350 | 1370 | KA600-2300 | 2300 | 2450 | 2470 |

| KA600-1300 | 1300 | 1450 | 1470 | KA600-2400 | 2400 | 2550 | 2570 |

| KA600-1400 | 1400 | 1550 | 1570 | KA600-2500 | 2500 | 2650 | 2670 |

| KA600-1500 | 1500 | 1650 | 1670 | KA600-2600 | 2600 | 2750 | 2770 |

| KA600-1600 | 1600 | 1750 | 1770 | KA600-2700 | 2700 | 2850 | 2870 |

| KA600-1700 | 1700 | 1850 | 1870 | KA600-2800 | 2800 | 2950 | 2970 |

| KA600-1800 | 1800 | 1950 | 1970 | KA600-2900 | 2900 | 3050 | 3070 |

| KA600-1900 | 1900 | 2050 | 2070 | KA600-3000 | 3000 | 3150 | 3170 |

| KA600-2000 | 2000 | 2150 | 2170 | |

L0: Effective measuring length of encoder L1: Dimension of encoder mounting hole

L2: Encoder overall dimension

KA-600 encoder, which is specifically designed for large machine tool, features in

large size and good rigidity. Support may be added to any position of the encoder to

enhance the rigidity and stability. The length is 1000~3000mm.

Detail Information:

All linear scales will be tested before delivery. Here is a sample of a scale's testing report.