Milling Lathe Grinder DRO Linear Glass Scale SINO KA600-2000mm With TTL 5um Grating Ruler Encoder Sensor

Add to Cart

Milling Lathe Grinder DRO Linear Glass Scale SINO KA600-2000mm TTL 5um Grating Ruler Encoder Sensor

Product Description:

The Milling Lathe Grinder DRO Linear Glass Scale, specifically the

SINO KA600-2000mm model, is an advanced digital readout (DRO)

system designed for precision measurement and control in milling,

lathe, and grinding operations. This high-quality system

incorporates a linear glass scale and a TTL 5um grating ruler

encoder sensor for accurate and reliable position feedback.

Features:

Linear Glass Scale Technology: The DRO system utilizes a

high-precision linear glass scale, ensuring accurate and consistent

measurements of the milling, lathe, or grinding machine's axis

position.

TTL 5um Grating Ruler Encoder Sensor: The system features a

reliable TTL 5um grating ruler encoder sensor, providing precise

position feedback and facilitating real-time monitoring and

control.

Versatile Functionality: This DRO system supports multiple

applications, including milling, lathe, and grinding operations,

making it a versatile solution for various machining tasks.

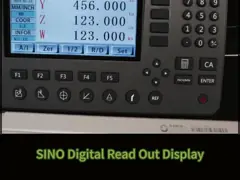

Clear Digital Display: The DRO unit is equipped with a clear

digital display that presents accurate numerical readings, enabling

operators to make precise adjustments to achieve desired machining

outcomes.

Easy Installation and Operation: Installing and setting up the

Milling Lathe Grinder DRO is a straightforward process, and its

user-friendly interface ensures hassle-free operation.

Package includes:

KA500-2000mm linear glass scale, one piece.

There is a resolution of 0.5/1/5um.

Depending on the requirements of the customers, customized encoder lengths (L0) can be offered.(Length:1000-3000mm)

The SINO KA600 linear scale is known for its high precision, durability, and resistance to environmental factors such as dust, temperature variations, and vibrations. It is commonly used in conjunction with milling machines, lathes, coordinate measuring machines (CMMs), and other industrial equipment that require precise positioning or dimensional measurements.

The operation of an absolute optical angle encoder typically

involves a rotating disc or ring that contains a pattern of optical

markings or codes. These markings are read by optical sensors or

detectors, which convert the optical patterns into electrical

signals. The electrical signals are then processed to determine the

absolute angular position.

The optical markings on the encoder disc or ring can take various forms, such as binary codes, gray codes, or analog signals. The number of markings or codes determines the resolution or precision of the encoder. Higher-resolution encoders have more markings or codes, allowing for finer angular resolution.

| Model | L0 | L1 | L2 | Model | L0 | L1 | L2 |

| KA600-1000 | 1000 | 1150 | 1170 | KA600-2100 | 2100 | 2250 | 2270 |

| KA600-1100 | 1100 | 1250 | 1270 | KA600-2200 | 2200 | 2350 | 2370 |

| KA600-1200 | 1200 | 1350 | 1370 | KA600-2300 | 2300 | 2450 | 2470 |

| KA600-1300 | 1300 | 1450 | 1470 | KA600-2400 | 2400 | 2550 | 2570 |

| KA600-1400 | 1400 | 1550 | 1570 | KA600-2500 | 2500 | 2650 | 2670 |

| KA600-1500 | 1500 | 1650 | 1670 | KA600-2600 | 2600 | 2750 | 2770 |

| KA600-1600 | 1600 | 1750 | 1770 | KA600-2700 | 2700 | 2850 | 2870 |

| KA600-1700 | 1700 | 1850 | 1870 | KA600-2800 | 2800 | 2950 | 2970 |

| KA600-1800 | 1800 | 1950 | 1970 | KA600-2900 | 2900 | 3050 | 3070 |

| KA600-1900 | 1900 | 2050 | 2070 | KA600-3000 | 3000 | 3150 | 3170 |

| KA600-2000 | 2000 | 2150 | 2170 | |

L0: Effective measuring length of encoder L1: Dimension of encoder mounting hole

L2: Encoder overall dimension

KA-600 encoder, which is specifically designed for large machine tool, features in

large size and good rigidity. Support may be added to any position of the encoder to

enhance the rigidity and stability. The length is 1000~3000mm.

Detail Information:

All linear scales will be tested before delivery. Here is a sample of a scale's testing report.