Add to Cart

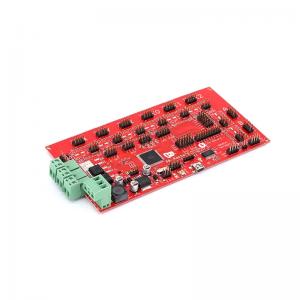

Reflow Oven FUJI NXT3 PCB Assembly service Main PCBA Quick Turn

Finding Solutions to the Semiconductor Supply Chain Problem

The best way to work around the semiconductor shortage is to partner with someone who has a lot of experience working with the component supply chain, like CESGATE. The component engineers and procurement specialists at a PCB contract manufacturer ha

ve the necessary skill set for this job. They can bring the following assets to the table when the time comes to purchase parts for your next PCB build:

Knowledgeable component engineering resources

Purchasing agents experienced working in the component supply chain

A vast network of component manufacturers, distributors, and

brokers

Software tools for advanced alerts of component life-cycle changes

Extensive training to spot and avoid counterfeit parts and vendors

At CESGATE, we have the component experts that you need to navigate the ever-evolving semiconductor shortages. Our team can help you work around the component shortages by finding the best part choices for price and delivery to keep your Main PCBAon schedule. If a component has been discontinued, our engineers will work together with you to find the correct replacement parts that are form, fit, and functionally compatible.

SMT lines

Our company currently has 7 wave soldering production lines and 10 post-DIP soldering lines. We can make special fixtures according to customer requirements and product conditions to ensure product reliability and effectively improve plug-in efficiency.

Our DIP post-welding personnel have rich experience for Main PCBA, and have formulated detailed standardized operation guidelines and SOP operation instructions to meet the high-quality requirements of high-end customers.

Advantages of CESGATE:

CESGATE is the professional PCB and Main PCBA Manufacturer, can provide one-stop service from PCB/PCBA Design, PCB/PCBA Clone, PCB manufacturing, Components sourcing, PCB Assembly, and fully product assembly and test. We have got certification of ISO 9001, ISO 13485 and UL. Our capacity including: 1-32 layers FR4 PCB board manufacturing, 1-12 layers Flexible PCB manufacturing, Aluminum PCB and Ceramic PCB manufacturing, can finish about 324000pcs PCBA per months.

Specification

| NO. | Items | Capabilities |

| 1 | Layers | 2-68L |

| 2 | Maximum machining size | 600mm*1200mm |

| 3 | Board thickness | 0.2mm-6.5mm |

| 4 | Copper thickness | 0.5oz-28oz |

| 5 | Min trace/space | 2.0mil/2.0mil |

| 6 | Minimum finished aperture | 0. 10mm |

| 7 | Maximum thickness to diameter ratio | 15:1 |

| 8 | Via treatment | Via, blind&buried via, via in pad, Copper in via … |

| 9 | Surface finish/treatment | HASL/HASL lead free, Chemical tin, Chemical Gold, Immersion gold Inmersion Silver/Gold, Osp, Gold Plating |

| 10 | Base Material | FR408 FR408HR, PCL-370HR;IT180A, Megtron 6(Panasonic);Rogers4350, Rogers4003, RO3003, Rogers/Taconic/Arlon/Nelco laminate with FR-4 material(including partial Ro4350B hybrid laminating with FR-4) |

| 11 | Solder mask color | Green.Black.Red.Yellow.White.Blue.Purple.Matte Green. Matte Black |

| 12 | Testing Service | AOI, X-Ray, Flying-Probe, Function Test, First Article Tester |

| 13 | Profiling Punching | Routing,V-CUT,Beveling |

| 14 | Bow&twist | ≤0.5% |

| 15 | HDI type | 1+n+1,2+n+2,3+n+3 |

| 16 | Min mechanical aperture | 0.1mm |

| 17 | Min laser aperture | 0.075mm |

Company Profile

Producing a qualified product is crucial to CESGATE and to you. To ensure Main PCBA are compliant we use a number of inspection and Quality assurance procedures. Including Automatic Optical Inspection equipment and CAD software as well as continuous improvements. We are accredited to ISO9001: 2015 as well as being a preferred supplier to many of our customers. With access to global suppliers, and distribution networks we can source parts for your assemblies as needed. Using our own in-house Stock and MRP system which links to our production data we are able to manage Inventory levels, lead times and buffer stocks to meet your deadlines.

FAQ

| Q: Can your company provide the serial number when making circuit

board text? CESGATE: Serial numbers can be provided, and in addition to text serial numbers, QR-CODE can also be provided for customers to query. |

| Q: How long is the shelf life of the PCB board and how should it be

stored? CESGATE: 25℃ / 60%RH is recommended when the PCB is stored. The plate itself has no shelf life, but if it exceeds three months, it needs to be baked to remove moisture and stress, and it should be used immediately after baking. It is recommended that the pieces should be loaded within 6 months of storage to reduce the phenomenon of rejection and explosion. |

| Q: What is your delivery date? CESGATE: The general sample delivery time is 6 working days for single and double-sided boards, 7 working days for 4-layer boards, and an additional working day for every 2 layers. However, if there are special processes, additional working days will be added according to the situation. Generally, the delivery time for mass production is 10 working days for single and double-sided panels, and 15 working days for multi-layer panels. However, if there is a special process or more than a certain number of working days, the working days will be additionally increased according to the situation; you can also pay the urgent fee to shorten the number of days, please contact Contact the business specially proposed, depending on the individual situation to provide expedited days. |

| Q: What is the difference between the HDI board and the general

circuit board? CESGATE: Most of HDI use laser to form holes, while general circuit boards only use mechanical drilling, and HDI boards are manufactured by the build-up method (Build Up), so more layers will be added, while general circuit boards are only added once. |