Company Profile

Mingxuan company was founded in 2007, and has been developed into a

high-tech enterprise which integrates scientific and technological

research and development, comprehensive design, production and

manufacturing, installation and commissioning, general contracting,

project investment and operation.

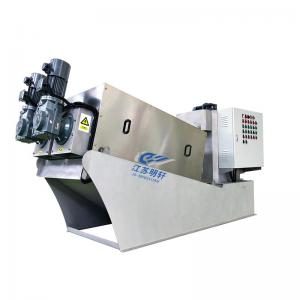

The company is committed to the development and research of solid

waste treatment technology and equipment (including kitchen waste,

sludge, etc.), with the efforts of all colleagues of the company,

it has obtained more than 30 national patents on kitchen waste

equipment and sludge treatment equipment. The company has passed

ISO quality management certification, environmental management

system certification, occupational health and safety management

system certification, as well as national high-tech enterprises and

other honors.